By: George Mathew

Artificial Intelligence (AI) is leading the charge in innovation within the supply chain. The rapid evolution of the supply chain, coupled with the increasing adoption of AI applications, is unmistakably evident. Over the upcoming years, AI is poised to transform the supply chain process profoundly, propelling productivity and efficiency to unprecedented levels. Organizations leverage AI-powered algorithms and sophisticated data analysis techniques to extract valuable insights from extensive datasets, thereby enhancing operational efficiency and informing strategic decision-making processes.

The potency of AI in supply chain analytics stems from its capacity to swiftly and accurately process vast amounts of data, surpassing the capabilities of human analysis in terms of both speed and precision. Through predictive analytics, AI enables accurate demand forecasting, optimizing inventory levels and enhancing overall supply chain efficiency. Automation, powered by AI, streamlines routine tasks, from order fulfillment to inventory management, reducing errors and improving operational speed. AI’s ability to identify and manage risks enhances resilience, while continuous learning through machine learning ensures ongoing optimization of supply chain processes. Overall, AI transforms supply chain analytics by providing real-time insights, improving decision-making, and fostering agility in response to dynamic market conditions.

Key aspects of the role of AI in supply chain analytics:

Conducting accurate forecasting and proficiently managing inventory

AI algorithms analyze historical data, market trends, and external factors such as weather or economic indicators to predict future demand. By leveraging machine learning, businesses can optimize inventory levels, reduce carrying costs, and minimize the risks of stockouts or overstocking. This data-driven approach enables more efficient supply chain management and better adaptation to changing market conditions, ultimately improving overall operational efficiency.

Streamlining route planning for maximum efficiency

In supply chain management, route optimization involves leveraging AI-powered algorithms to determine the most efficient paths for transporting goods. These algorithms take into consideration various factors, including traffic conditions, weather patterns, and delivery windows. By optimizing transportation routes, businesses can achieve cost savings, enhance on-time deliveries, and contribute to a more sustainable operation by minimizing the environmental impact through reduced fuel consumption and emissions.

Enhanced management of supplier relationships

AI enables more sophisticated and predictive supplier relationship management, offering insights into supplier performance, risk mitigation, and demand forecasting. By leveraging AI, businesses can enhance communication, streamline procurement processes, and optimize inventory levels. This technology contributes to a more resilient and adaptive supply chain, ultimately improving overall efficiency and fostering stronger, mutually beneficial partnerships with suppliers.

Streamlined and efficient warehouse management

AI optimizes warehouse operations by enhancing tasks like inventory management, order fulfillment, and demand forecasting. Through real-time data and machine learning algorithms, AI facilitates smart decision-making, reducing errors and improving overall accuracy in inventory tracking. AI-driven robots further revolutionize processes such as picking, packing, and inventory tracking, resulting in faster order fulfillment and significant labor cost reduction. This integration ensures efficient warehouse operations, accurate inventory management, and swift processing of customer orders, contributing to a streamlined and cost-effective supply chain.

Effective risk mitigation

AI technologies like predictive analytics and machine learning enable businesses to proactively identify and anticipate supply chain risks, from disruptions to demand fluctuations. Real-time data analysis enhances decision-making, providing actionable insights for effective risk mitigation strategies. AI’s dynamic risk models adapt to changing conditions, improving assessment accuracy. This proactive approach allows timely implementation of contingency plans, minimizing disruption impact and enhancing overall supply chain resilience.

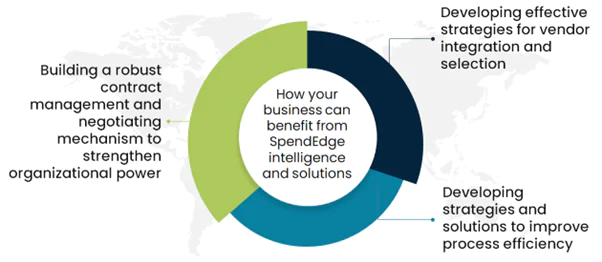

How SpendEdge can assist in seamlessly integrating AI in supply chain processes to enhance overall efficiency:

Developing effective strategies for vendor integration and selection

Our sourcing experts play a critical role in helping companies navigate complex procurement issues. Our experts help businesses choose the best software providers and integrate their products with ease into their existing infrastructure. Vendor assessment, negotiation, implementation, quality control, and ongoing support are all included in our extensive offerings. In addition, our professionals offer professional advice on requirements analysis, market research, vendor assessment, strategy formulation, and risk management, ensuring that businesses make wise and economical choices.

Developing strategies and solutions to improve process efficiency

Our experts offer an organized approach to streamline an organization’s purchasing procedures. We help companies integrate procurement AI technologies that support their goals by doing a thorough assessment of their present procedures, carefully identifying the needs of each organization, and developing a customized plan. Long-term, this leads to increased effectiveness and cost-effectiveness.

Building a robust contract management and negotiating mechanism to strengthen organizational power

Our advisors’ expertise plays a crucial role in navigating negotiations to achieve a comprehensive and advantageous agreement. Our specialists assist in negotiating advantageous terms and conditions for the purchase of AI-powered systems and software. This entails precise deliverables, reasonable timeframes, and mutually advantageous pricing arrangements that best serve the organization’s objectives and promote a positive working relationship with the solution provider.

Success Story: How we helped the well-known CPG company in optimizing their supply chain process

Our client is a US-based, leading consumer packaged goods (CPG) company, specializing in manufacturing and marketing of diverse range of products.

The client encountered difficulties in streamlining its supply chain processes by incorporating AI technologies, particularly in the area of supplier intelligence. The goal was to leverage these technologies to secure a competitive advantage in the market.

Our experts at SpendEdge conducted a thorough market analysis in the CPG industry, identifying potential suppliers through industry reports, trade shows, and online databases. They evaluated suppliers based on criteria like quality, reliability, scalability, and sustainability, utilizing a comprehensive framework. Historical performance data, on-site visits, and stakeholder interviews informed our supplier categorization into strategic, tactical, and commodity segments. Simultaneously, our experts identified pain points and technology gaps in the existing supply chain, benchmarked the client against competitors, and aligned technology recommendations with their needs. Our roadmap for AI solution implementation ensured seamless integration with existing systems, collaborating closely with the client’s IT department for a smooth transition and enhanced operational efficiency.

Our solutions have markedly improved the client’s operational efficiency, risk management, and competitive standing in the CPG industry. The successful alignment of technology solutions with their needs has laid the groundwork for sustainable growth and ongoing innovation.

Contact us now to solve your procurement problems!

Author’s Details

George Mathew

Associate Vice President, Sourcing and Procurement Intelligence

George is a procurement specialist at Infiniti Research and provides advisory services to clients across the pharmaceutical, CPG & FMCG, energy, and automotive sectors. He specializes in the procurement areas of industry benchmarking, cost modeling, rate card benchmarking, negotiation advisory, and supplier intelligence.