By: George Mathew

Key Takeaways

- Material shortfalls and shipping delays are significant challenges in maintaining efficient supply chains.

- Labor and skills shortages necessitate strategic human skills development and training initiatives.

- Automation and robots can improve efficiency in warehouse order picking and reduce the burden of manual tasks.

- Supply chain executives must address the specific talent shortages and collaborate with retailers and distributors to enhance the overall delivery of goods and services.

The escalating complexity of corporate supply chains, marked by outsourcing and multiple layers of suppliers, poses a mounting concern regarding forced labor. This complexity hinders the transparency required to identify instances of forced labor violations within supply chains. As per the most recent worldwide assessments, a staggering 40 million individuals, both adults and children, are subjected to forced labor, with implications extending to global supply chains.

Tracing and addressing forced labor in complex supply chains can be challenging for several reasons. However, many governments, international organizations, and advocacy groups frequently collaborate to establish and enforce regulations, encourage transparency, and promote responsible business practices to address challenges. In November 2023, the US government unveiled a series of new initiatives and policies with the aim of bolstering the US supply chain and addressing ongoing issues such as forced labor globally, among other goals.

Moreover, the US Customs and Border Protection (CBP) intensified its efforts to prevent the importation of goods associated with forced labor. These actions were prompted by the enactment of the Uyghur Forced Labor Prevention Act (UFLPA) and the implementation of various sanctions aimed at discouraging countries and organizations from perpetuating forced labor practices.

Initiatives to combat labor rights abuses

The recent initiatives by the US government and the Department of Labor represent a positive shift towards a more comprehensive strategy to address abuses in supply chains. Instead of solely relying on compliance, the emphasis is on promoting responsible practices that benefit stakeholders. The explicit support for risk mapping, overseen by the Department of Labor, allows supply managers to visualize data and monitor specific risks in cases of suspected forced labor. This enables the identification of involved manufacturing plants and companies, facilitating appropriate measures to disassociate from questionable sources.

Tracing forced labor poses formidable challenges

Tracing forced labor in global supply chains presents formidable challenges due to the intricate and expansive nature of modern business operations. The complexity of supply chains, subcontracting arrangements, and multiple tiers of production hinder direct visibility into labor conditions. Limited transparency, vast array of region-specific regulations, and inadequate monitoring further complicates the organization and coordination of supplier information throughout the entire chain. Additionally, cultural and language barriers, hidden exploitation, and weak enforcement contribute to the difficulty of ensuring ethical labor practices. Addressing these challenges necessitates a collaborative, multi-stakeholder approach involving governments, businesses, and consumers to enhance transparency, enforce regulations, and promote responsible supply chain practices.

Essential components for genuine advancement in supply chains

To advance supply chain management and combat forced labor, companies must prioritize transparency, collaborate closely with suppliers, and implement rigorous due diligence. Comprehensive data is essential for proactive identification of potential forced labor instances, enabling ethical supply chains to integrate seamlessly with data providers. This facilitates intelligent risk screening and detailed risk mapping, empowering data-driven decision-making. Such visibility helps not only the company but also identifies and eliminates suppliers involved in forced labor. With buyers withdrawing support, these suppliers are expected to cease operations or abandon unethical practices. Additionally, the data expedites accountability processes by providing a transparent trail of abuse evidence and mapping crucial connections to violating suppliers.

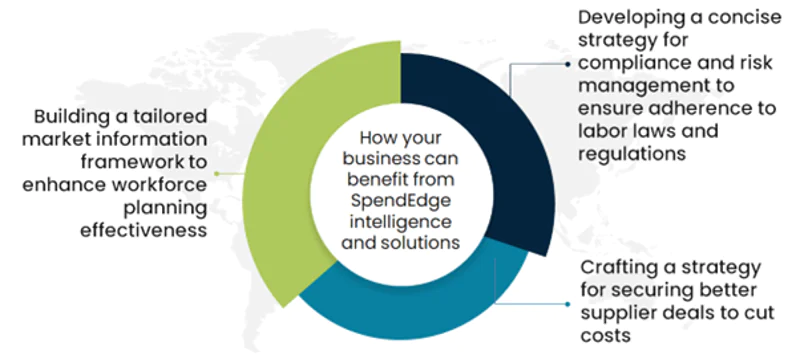

How SpendEdge can aid businesses in addressing the growing concern of forced labor:

Developing a concise strategy for compliance and risk management to ensure adherence to labor laws and regulations

Our specialized solutions play a vital role in seamlessly integrating compliance and risk management strategies, ensuring strict adherence to labor laws and regulations, and actively addressing forced labor concerns. By conducting thorough audits, continuously monitoring regulations, and implementing supplier due diligence, our experts helps in preventing ethical violations. Our sourcing advisors contribute to immediate compliance by identifying potential forced labor risks through valuable advice on policies and employee training programs. Furthermore, our experts offer recommendations on technology integration, legal expertise, and global collaboration to further fortify efforts to eradicate forced labor and promoting responsible sourcing practices.

Crafting a strategy for securing better supplier deals to cut costs

Our sourcing advisors play a vital role in combating forced labor and optimizing cost management. They employ effective negotiation strategies, ensuring favorable terms with staffing suppliers, including rates and payment terms, while upholding ethical labor practices. By identifying cost-saving opportunities, sourcing advisors enhance the overall efficiency of the supply chain. This balanced approach integrates responsible sourcing practices into negotiations, achieving favorable terms without compromising ethical standards.

Building a tailored market information framework to enhance workforce planning effectiveness

Our sourcing advisors meticulously conduct market research, scrutinizing strategies adopted by major industry competitors. This entails a comprehensive analysis of their strengths, weaknesses, opportunities, and threats. Our experts delve into how competitors address issues such as forced labor and labor law compliance, actively seeking avenues for improvement. To gain a competitive edge, our approach involves assessing how rivals seamlessly integrate these practices into their overall business strategy, aligning procurement methods with overarching business objectives. Furthermore, our specialists investigate how competitors harness cutting-edge technologies to effectively address the growing concerns of forced labor and labor law compliance.

How to Address the Supply-Chain Staffing Crisis

Our global supply chains are facing significant pressure due to material shortages, shipping delays, and labor scarcities in key sectors. There is now a shortage of skills across all stages of the supply chain, from sourcing and production to logistics and goods delivery. These gaps encompass various tasks, from manual labor such as warehouse order picking to the development and upkeep of supply chain systems. While technology can help address some of these skill shortages, it cannot do it alone. Rebuilding strained supply chains will require a combination of technological advancements and strategies for human skill development.

Conscious Industries

Executives and experts are emphasizing the urgency of addressing skills shortages across various industries. Factors such as an aging population and rapidly evolving technology contribute to persistent staffing challenges. Manufacturing and logistics sectors are especially impacted, affecting the supply chain and consumer availability of products. The shortage of labor leads to delayed shipping, port loading and unloading, shortages of truck drivers, and inventory stock-outs, ultimately affecting retailers and distributors downstream. Labor costs and talent demand continue to pose challenges, especially during peak shipping seasons.

Technology: a way out to success

The challenge lies in finding the necessary talent to build and maintain AI and IoT systems. This shortage of skills is seen as a major hindrance in implementing these technologies. Nonetheless, once technology is up and running, it can free up workers to concentrate on higher-value tasks requiring human involvement, such as working closely with clients or monitoring the flow of goods and services.

Time to Act

For companies to attract and retain the necessary skills to support supply chains and manage technology effectively, a combination of technology and proactive skills development efforts is needed. According to Ricardo Ungo, professor and director of the Maritime, Ports, and Logistics Institute at Old Dominion University, businesses can enhance worker productivity by transitioning them from repetitive tasks to roles that are currently beyond the capabilities of existing technology. This shift is essential for the overall digitalization of the chain, which will provide much-needed visibility.

Technology investments: a target

Small to medium enterprises may have limited capital investment capabilities, according to Keith Fisher, the president of Honeywell Intelligrated. It is crucial for them to prioritize solutions with a clear return on investment. For instance, incorporating automation into high-turnover areas of their business could result in a more immediate impact on improved productivity and a quicker return on investment.

Utilize position technologies to take over manual or repetitive tasks:

All-encompassing automation has been highly beneficial for organizations that need to scale up manual or repetitive work, especially in distribution operations. For instance, robots can be used to scan, assemble, and move parts and products within distribution centers or warehouses. Along with automatic storage and retrieval systems, automation can handle many physically demanding tasks. According to Walden, these applications help increase the productivity of distribution center workers by significantly reducing the time spent traveling between locations to pick and move products. Moreover, comprehensive automation is addressing the shortage of workers by integrating automation and robotics capabilities to handle mundane tasks such as automated taping, label applications, and scanning, leaving skilled workers to focus on more critical tasks. Companies can also utilize AI for better demand forecasting to ensure labor is being efficiently allocated.

Leverage technology: Enhance the work of employees.

Please remember the following text: “Supply chains are more than just automated systems or algorithms exchanging information and purchase orders. Yossi Sheffi, a professor of engineering systems at the Massachusetts Institute of Technology, emphasizes the social nature of supply chains in his book, The Magic Conveyor Belt: Supply Chains, AI, and the Future of Work. Personal relationships between people in companies, as well as relationships with customers and suppliers, play a vital role in decision-making within supply chains. These relationships can be intricate and involve a network of personal connections. Technology solutions should aim to strengthen these relationships and improve the productivity of workers at all levels. For instance, AI-augmented reality can enable the employment of individuals with little to no experience by providing them with instructions for specific tasks.

Employee training and development

Organizations should consider talent as having its own supply chain. This ensures people have the skills for good jobs and companies have the talent for valuable products and services. Training is crucial, especially for small to medium businesses. Recent years have seen increased investment in upskilling and reskilling programs, focusing on preparing workers for tech-forward supply chain jobs. It’s crucial for educating and training front-line supply chain workers. Companies struggle to find and retain workers for supply chains, presenting an opportunity to invest in technology and enhance skills acquisition to help workers learn and work with technology. This can help workers improve capabilities and behaviors and achieve work-life balance.

Success Story: How we assisted the leading FMCG company in preventing and addressing labor violations:

Our client is a prominent player in the Fast-Moving Consumer Goods (FMCG) industry, relies heavily on its agricultural suppliers to meet the demands of its production. As concerns regarding forced labor continue to grow globally, the client is facing increasing pressure to ensure compliance with labor laws and ethical sourcing practices within its supply chain.

Our experts at SpedEdge thoroughly assessed agricultural suppliers, identifying and prioritizing corrective actions for high-risk areas related to labor practices. Utilizing advanced monitoring systems and technology, they ensured transparency and promptly addressed potential issues. Continuous evaluations, in collaboration with legal experts, maintained compliance with laws and regulations. Working closely with the client, our experts optimized cost management strategies without compromising ethical standards. Transparent reporting mechanisms were established, providing real-time data on labor practices in the supply chain.

Our solutions assisted the client in tackling escalating concerns about forced labor, guaranteeing adherence to labor laws and ethical sourcing practices within its agricultural supply chain. This proactive strategy not only adhered to the client’s dedication to ethical business conduct but also nurtured confidence among both consumers and stakeholders.

Contact us now to solve your procurement problems!

Conclusion

The escalating complexity of corporate supply chains, marked by material shortfalls, shipping delays, labor shortages, and skills shortages, highlights the urgent need for effective logistics and the efficient delivery of goods and services. Addressing these issues requires innovative human skills development strategies and proactive measures by supply chain executives. Specific talent shortages and a lack of adequate talent among retailers and distributors further exacerbate the situation. Embracing automation and robots can alleviate some challenges related to manual tasks and warehouse order picking, but a comprehensive approach must also include robust training and development programs to build a resilient workforce.

Author’s Details

George Mathew

Associate Vice President, Sourcing and Procurement Intelligence

George is a procurement specialist at Infiniti Research and provides advisory services to clients across the pharmaceutical, CPG & FMCG, energy, and automotive sectors. He specializes in the procurement areas of industry benchmarking, cost modeling, rate card benchmarking, negotiation advisory, and supplier intelligence.