By: Manpreet Kaur

In today’s competitive business landscape, every penny saved can contribute significantly to a company’s bottom line. One area where businesses can often find opportunities for savings is in packaging costs. Packaging plays a crucial role in product presentation, protection, and shipping, but excessive spending in this area can eat into profits. Fortunately, there are several strategies businesses can employ to reduce packaging costs and boost profitability without compromising quality or customer satisfaction.

What Factors Contribute to Higher Packing Costs?

- Fragile or bulky items require special packaging materials.

- Customized packaging solutions for unique products.

- Shipping long distances or internationally necessitates extra protective measures.

- Compliance with strict industry or regulatory packaging standards.

- Use of specialized packaging machinery or technology.

- Demand fluctuations lead to inventory management challenges.

- Customization for individual customer orders, increasing handling time and materials usage.

How can implementing procurement software benefit organizations?

The benefit of a personalized catalogue:

A personalized catalog within procurement software offers tailored product listings based on individual user preferences and historical purchasing data. This feature streamlines procurement processes by presenting users with relevant and preferred items, enhancing efficiency, and reducing search time. By providing a curated selection that aligns with user needs, personalized catalogs improve user satisfaction, drive compliance with preferred suppliers, and ultimately optimize procurement spend. This tailored approach boosts productivity, fosters strategic procurement decisions, and contributes to overall cost savings for organizations.

Reduction in lead times:

Procurement software facilitates reduced lead times by optimizing the sourcing process with localized supply options. By integrating local suppliers into the procurement ecosystem, the software enables quicker access to goods and services, minimizing delays associated with international shipping and customs clearance. This localization enhances agility in response to demand fluctuations, mitigates risks related to global disruptions, and fosters stronger supplier relationships. Consequently, organizations can fulfill orders faster, meet customer expectations more effectively, and maintain a competitive edge in the market.

Procurement software enables efficient price benchmarking:

Procurement software facilitates efficient price benchmarking by aggregating and analyzing pricing data from multiple suppliers or markets. This enables procurement professionals to compare prices for similar products or services across various suppliers, regions, or timeframes. By providing comprehensive insights into market trends and pricing dynamics, the software empowers users to negotiate better deals and identify cost-saving opportunities. Additionally, advanced analytics tools within the software enable users to conduct in-depth analyses, such as price variance analysis and cost breakdowns, further enhancing their ability to benchmark prices effectively.

Managing delivery locations and SKUs:

Procurement software streamlines the management of delivery locations and SKUs by centralizing data and providing robust tracking capabilities. Users can efficiently track inventory levels, monitor SKU availability across multiple locations, and manage delivery schedules with ease. By offering real-time visibility into stock levels and delivery statuses, the software enhances inventory management accuracy and reduces the risk of stockouts or overstocking. Additionally, it enables users to optimize delivery routes, minimize transportation costs, and improve overall logistics efficiency. Ultimately, procurement software empowers organizations to effectively manage their delivery locations and SKUs, ensuring timely deliveries and optimized inventory levels for enhanced operational performance.

Enhances visibility into the procurement process:

Procurement software enhances visibility into the procurement process by centralizing and digitizing key procurement activities. It provides real-time access to comprehensive data and analytics, offering insights into every stage of the procurement lifecycle. Users can monitor requisitions, purchase orders, supplier performance, and contract management from a single platform. This visibility enables stakeholders to track progress, identify bottlenecks, and make informed decisions promptly. Additionally, advanced reporting and analytics functionalities within the software provide deeper insights into spending patterns, supplier relationships, and compliance metrics.

Advantage of data-driven analytics:

Data-driven analytics within procurement software offer several advantages. By analyzing historical spending patterns, supplier performance, and market trends, organizations can identify cost-saving opportunities, negotiate better contracts, and optimize supplier relationships. These insights enable informed decision-making, driving strategic procurement initiatives and enhancing operational efficiency. Additionally, data-driven analytics help mitigate risks by identifying potential supply chain disruptions and enabling proactive risk management strategies. Moreover, by tracking key performance indicators and compliance metrics, organizations can ensure alignment with corporate objectives and regulatory requirements.

Eases the process of invoicing:

Procurement software streamlines the invoicing process by automating and centralizing invoicing activities. It enables users to create, manage, and track invoices electronically, eliminating manual errors and delays associated with paper-based invoicing. By integrating with accounting systems and supplier portals, the software facilitates seamless communication between buyers and suppliers, ensuring accurate and timely invoicing. Additionally, it provides customizable templates and workflows for invoice approval, reducing processing time and improving accuracy. With features like automated matching of invoices to purchase orders and contracts, procurement software enhances transparency and compliance while simplifying reconciliation tasks.

Request a proposal of our services at SpendEdge that can help you understand the packing costs and minimise procurement expenses

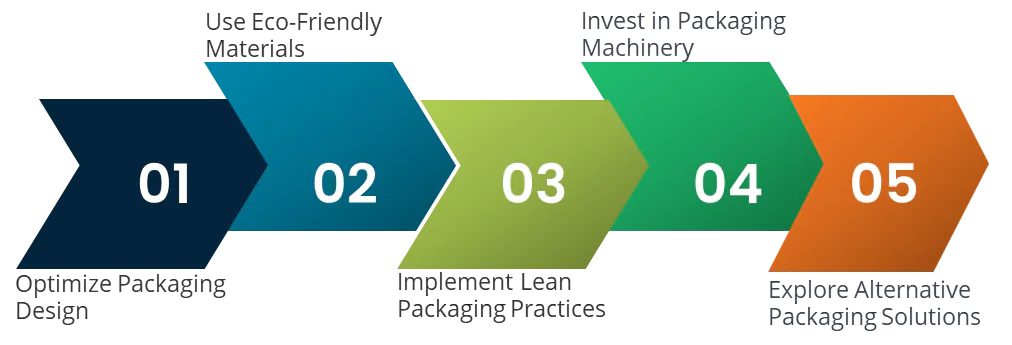

Effective Strategies to Control Packaging Expenses

- Optimize Packaging Design: One of the most effective ways to reduce packaging costs is by optimizing the design. Look for ways to minimize material usage while maintaining product protection. This might involve redesigning packaging to be more compact or lightweight. Utilizing packaging design software or consulting with packaging engineers can help identify opportunities for improvement.

- Use Eco-Friendly Materials: Sustainable packaging not only appeals to environmentally conscious consumers but can also help reduce costs in the long run. Materials such as recycled cardboard, biodegradable plastics, and compostable packaging offer eco-friendly alternatives that can often be more cost effective than traditional materials. Additionally, lightweight materials can reduce shipping costs while still providing adequate protection.

- Implement Lean Packaging Practices: Adopting lean principles in packaging operations can help streamline processes and eliminate waste. Analyze the entire packaging process from procurement to disposal to identify inefficiencies and areas for improvement. Just-in-time inventory management can reduce storage costs and minimize excess inventory, while automation can improve efficiency and reduce labor costs.

- Invest in Packaging Machinery: While there may be upfront costs involved, investing in packaging machinery can lead to significant long-term savings. Automated packaging equipment can increase efficiency, reduce labor costs, and minimize material waste. Evaluate the ROI of investing in machinery based on anticipated cost savings over time.

- Explore Alternative Packaging Solutions: Sometimes, traditional packaging methods may not be the most cost-effective option. Explore alternative packaging solutions such as pouches, shrink wrapping, or reusable containers that may offer cost savings compared to traditional boxes or containers. Conduct thorough cost comparisons to determine the most economical solution for your products.

- Monitor and Optimize Shipping Costs: Shipping expenses can make up a significant portion of packaging costs. Analyze shipping methods, carrier rates, and packaging dimensions to identify opportunities for cost savings. Negotiate shipping rates with carriers based on shipping volume and explore options such as regional carriers or freight consolidation to reduce costs.

- Regularly Review and Adapt Strategies: The business landscape is constantly evolving, so it’s essential to review packaging strategies and adapt as needed regularly. Stay informed about industry trends, technological advancements, and regulatory changes that may impact packaging costs. Continuously seek opportunities for innovation and improvement to stay ahead of the competition.

Conclusion

By implementing these strategies, businesses can effectively reduce packaging costs while simultaneously enhancing profitability. From optimizing packaging design to leveraging sustainable materials and streamlining operations, there are numerous avenues for cost savings in packaging. By prioritizing efficiency, innovation, and sustainability, businesses can achieve their financial goals while delivering quality products to customers.

Get a free trial of our professional services and see how it helps your business

Author’s Details

Manpreet Kaur

Assistant Manager Presales – Sourcing and Procurement Intelligence

Manpreet is a presales specialist at Infiniti Research and has expertise in sales, business strategy execution, and innovative solution design. She is actively involved in supporting clients from F&B, CPG, Healthcare, Pharma, Chemicals, BFSI, Oil & Gas and Automotive sectors.