By: George Mathew

Key Takeaways

- Cost Efficiency: Strategic sourcing helps reduce costs and optimize packaging processes, leading to substantial savings.

- Supplier Evaluation: Comprehensive assessment of suppliers ensures quality, sustainability, and reliability.

- Sustainability: Emphasizing eco-friendly packaging solutions enhances brand image and aligns with environmental goals.

- Adaptability: Staying informed about industry trends and regulatory changes enables proactive adjustments in procurement strategies.

The packaging sector has experienced substantial transformations in the supply market in recent years. Key macro factors, such as rapid growth in emerging markets, fluctuations in raw material prices, industry consolidation, adoption of circular economy practices, adherence to regulatory compliance, implementation of cost efficiency strategies, and a rising preference for premium and eco-friendly packaging, have exerted profound and enduring effects on the packaging supplier market. Additionally, given its integral role in business operations, the associated risks with the category, and the repercussions of price fluctuations on the final product, remain notably significant.

The role of digitalization in packaging procurement is pivotal, leveraging e-procurement platforms to streamline processes and enable data-driven decision-making. Strategies also prioritize supplier diversity for inclusivity and risk reduction. Collaboration with suppliers is essential for embracing packaging innovation and staying ahead of technological advancements. However, controlling packaging spend while meeting product marketing expectations poses challenges. Fluctuating raw material prices and limited risk mitigation options complicate cost controls. Expanding into new markets necessitates local sourcing skills for qualified suppliers, while supplier failures can disrupt operations and result in significant losses. Category managers must stay informed about technological developments and regulatory changes, potentially prompting shifts in sourcing strategies. Balancing these factors is essential for effective and resilient packaging procurement strategies.

What is strategic sourcing?

Strategic sourcing is an approach to supply chain management that formalizes the way information is gathered and used. It allows an organization to consolidate its purchasing power in order to find the best possible values in the marketplace and align its purchasing strategy with its business goals.

Revamping procurement strategies for packaging solutions to address fluctuating demands:

Strategies for navigating variations in demand for packaging materials

Efficiently respond to changes in demand by maintaining clear communication with product managers and suppliers. Assess the feasibility of meeting demands without altering procurement resources and, if necessary, clearly define scope changes. Evaluate existing packaging materials and collaborate with suppliers to explore alternatives if needed. Reassess quantities, adjust procurement plans, and consider the impact on costs in consultation with the finance team. Prioritize quality when seeking alternative materials, avoiding compromises. Mitigate risks by working closely with suppliers and staying informed about supply status. Adapt proactively to ensure timely acquisition and delivery of required materials.

Key factors to take into account when implementing change strategies

In response to temporary shifts in demand, it is crucial to prioritize new requirements when adjusting packaging procurement plans. Emphasizing the immediate impact on product quality, functionality, and safety over aesthetic changes is key, and consensus with product managers aids in efficient prioritization. Collaboration with suppliers ensures early bookings for materials that align with product specifications. Allocating a portion of inventory addresses potential demand variations, minimizing supply shortages. Maintaining regular communication with suppliers fosters responsiveness and support capabilities. Recording and analyzing procurement data facilitates informed decision-making in response to demand changes.

Navigating a dynamic procurement environment: Strategies for adaptation

Procurement professionals must proactively navigate market dynamics by monitoring trends, adapting strategies flexibly, considering environmental sustainability, collaborating with internal teams, and fostering a culture of continuous learning. Staying attuned to industry changes enables swift adjustments in procurement strategies, including exploring new suppliers and seizing market opportunities. Addressing environmental concerns involves adopting eco-friendly packaging materials, aligning with the industry’s sustainability goals. Close collaboration with internal teams ensures a unified approach during demand changes, emphasizing effective communication. Continuous learning through training and seminars ensures procurement professionals remain agile and well-prepared to navigate the challenges of a dynamic market.

Strategic Sourcing for Packaging

Companies frequently overlook the substantial savings opportunities that strategic sourcing can provide in the packaging and shipping suppliers category. Packaging plays a crucial role in a product’s success, significantly influencing its commercial or consumer appeal. Beyond aesthetic appeal, packaging is integral to the transportation, storage, and handling of your product, ensuring it reaches the customer in optimal condition. Despite its importance to both product presentation and logistics, packaging often remains an unmanaged category in many organizations.

Strategic sourcing for packaging involves a comprehensive approach to selecting suppliers and materials to achieve cost savings and operational efficiency. This process includes evaluating a wide range of packaging types and materials to meet diverse needs, such as protective, flexible, and custom packaging solutions.

Strategic sourcing also involves negotiating with suppliers to secure the best terms and pricing, considering factors such as material quality, sustainability, and supply chain reliability. By leveraging strategic sourcing, companies can optimize their packaging processes, reduce costs, enhance product appeal, and ensure efficient delivery to customers.

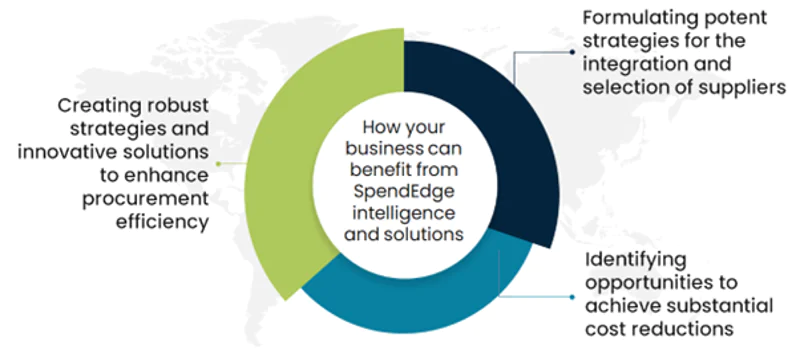

How SpendEdge can assist businesses in enhancing their procurement process for packaging solutions:

Formulating potent strategies for the integration and selection of suppliers

Our experts play a crucial role in formulating a procurement strategy for packaging. They initiate the process by establishing clear requirements and objectives, encompassing sustainability goals. This involves conducting comprehensive market research to pinpoint potential suppliers based on criteria such as reputation, experience, and geographical location. Suppliers are then evaluated on factors such as financial stability, production capacity, and adherence to quality standards. Furthermore, their innovation and sustainability practices are thoroughly assessed.

A meticulous risk assessment is performed, accompanied by a cost analysis, with negotiations conducted on pricing and terms. A concise recommendation is provided, taking into account supplier capabilities, cost-effectiveness, and alignment with objectives. Subsequently, an implementation plan is developed, encompassing supplier onboarding and continuous improvement processes to ensure the ongoing effectiveness and optimization of the strategy.

Identifying opportunities to achieve substantial cost reductions

Our proficiency in packaging procurement strategy is customized to prioritize sustainability, cost-effectiveness, and reliability. Our specialists employ advanced tools to collect category intelligence, monitor real-time raw material prices, and track supply and demand trends, ensuring adaptability in a timely manner. Market intelligence is derived from ongoing analysis of industry developments, and actionable research transforms insights into strategic decisions. Our sourcing experts conduct regular reviews and cross-functional collaboration ensure that sourcing approach remains responsive to dynamic market conditions, fostering an agile and well-informed procurement ecosystem.

Creating robust strategies and innovative solutions to enhance procurement efficiency

Our experts identify key competitors in your industry and conduct a thorough analysis of their packaging strategies. They assess how competitors align their packaging approaches with broader business goals, exploring innovations in packaging materials, design, and sustainability practices. Benchmarking your practices against those of competitors helps identify areas for improvement. Additionally, our experts emphasize staying abreast of local, national, and international regulations related to packaging and environmental standards. Developing a compliance tracking system is part of our strategy to ensure strict adherence to packaging regulations. Integrating compliance checks into your procurement process minimizes the risk of non-compliance.

Success Story: How we helped the prominent FMCG company in optimizing their procurement process for packaging solutions:

Our client is a leading Swiss Fast-Moving Consumer Goods (FMCG) company with a diverse product portfolio.

The client identified the need for a comprehensive packaging procurement strategy that integrates sustainability, reduces environmental impact, and ensures a responsible supply chain.

Our experts at SpendEdge meticulously analyzed the packaging industry, utilizing advanced tools to assess potential suppliers based on capabilities, financial stability, and sustainability practices. The selection process focused on environmental certifications, ethical practices, and a commitment to reducing the carbon footprint. Our experts prioritized suppliers with a track record of innovation in sustainable packaging. In-depth assessments of shortlisted suppliers evaluated technical capabilities, production capacity, and alignment with client specifications. The resulting recommendation report highlighted top suppliers with optimal capabilities and sustainability alignment. They also proposed contemporary sustainability practices, such as recyclable materials and bio-based plastics, while addressing existing gaps in the client’s processes. The client was benchmarked against industry leaders, and a roadmap was provided to exceed sustainability standards.

Our tailored packaging procurement strategy, focused on sustainability, positioned the client as an industry leader in the FMCG sector. The selection of suppliers with proven sustainable packaging capabilities, enhanced supply chain resilience. The implementation of modern sustainability practices not only resulted in cost savings but also fostered a positive brand image for the client.

Contact us now to solve your procurement problems!

Conclusion

Strategic sourcing in the packaging sector is essential for companies aiming to optimize costs, enhance product appeal, and ensure efficient logistics. By leveraging advanced tools, market intelligence, and a comprehensive supplier evaluation process, organizations can achieve significant savings, improve sustainability, and mitigate risks. Effective packaging procurement strategies not only align with business goals but also support innovation and compliance with regulatory standards. Companies that adopt strategic sourcing for packaging are better positioned to navigate market dynamics, respond to fluctuating demands, and maintain a competitive edge.

Author’s Details

George Mathew

Associate Vice President, Sourcing and Procurement Intelligence

George is a procurement specialist at Infiniti Research and provides advisory services to clients across the pharmaceutical, CPG & FMCG, energy, and automotive sectors. He specializes in the procurement areas of industry benchmarking, cost modeling, rate card benchmarking, negotiation advisory, and supplier intelligence.