By: George Mathew

Key takeaways

-

The food and beverage industry involves transforming raw agricultural goods into consumer-ready food categories using advanced production techniques and specialized equipment.

-

Food processing and packaging facilities ensure safe food handling and sustainability through innovations like edible packaging.

-

The industry includes fresh food, packaged food, and beverages, distributed across numerous retail outlets.

-

Addressing challenges in raw food production and optimizing the supply chain are crucial for maintaining quality and meeting regulatory requirements.

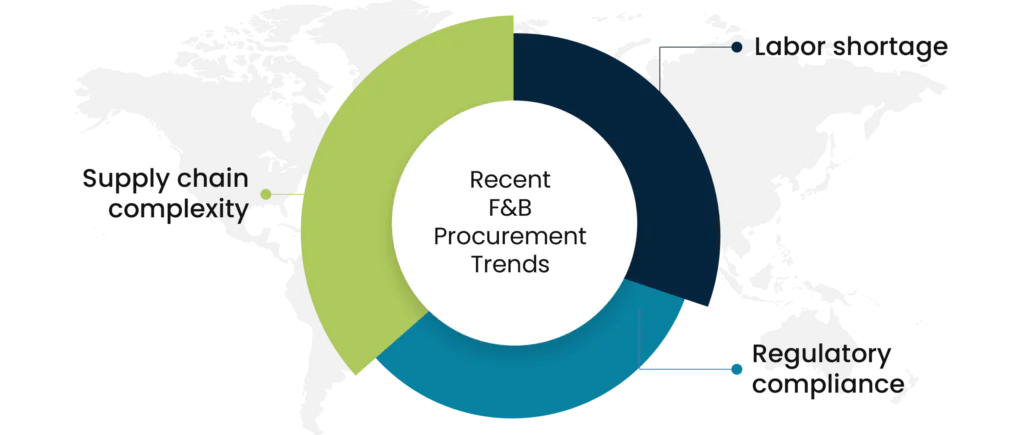

While sustainability, digitization, and transparency in supply chain are the key trends driving the food and beverages industry, quality assurance, regulatory compliance, and supply chain complexity are the top challenges.

Transparency in supply chain and sustainability in packaging and ingredients are the key demands echoing in the food and drinks industry. Consumers not only want to know from where the ingredients are sourced but also that they are packaged and procured in a sustainable manner. This has resulted in an emphasis on local sourcing and the use of recyclable packaging.

This trend has been a cause of concern for canned food manufacturers as tin and aluminum are widely used for packaging, and these products are non-biodegradable. To overcome this challenge and reduce environmental pollution, canned food manufacturers have started using recyclable tin and aluminum cans for packaging.

Similarly, compliance with regulatory standards, especially related to food safety and labeling, has been gaining prominence in the post-pandemic era.

Food and Beverage Industry – Overview

The Food and Beverage Industry includes all the companies involved in transforming raw agricultural goods into consumer food products. The overall industry supply chain includes food processing, packaging, and distribution. It does not cover raw food production, which falls into the closely related agriculture industry. This industry includes fresh food, packaged food, and beverages (both alcoholic and non-alcoholic). From food sold at the grocery store to cooked meals served at restaurants, institutions, and events, this industry serves a huge variety of retail outlets. Various production techniques are employed in the food processing stage to ensure quality and efficiency. The use of specialized equipment and food processing equipment in food processing plants is essential for the safe and effective transformation of raw materials.

Packaging machines and food packaging equipment play a crucial role in the packaging facilities, where products are prepared for the market. Innovations like edible packaging are gaining popularity due to their environmental benefits. Ensuring safe food handling throughout the supply chain is vital to maintaining the integrity and safety of food categories from the farm to the consumer. This includes careful management of the various stages of food processing and packaging, ensuring that both fresh food and packaged food meet stringent safety standards.

Recent Procurement Trends

Adoption of technology-enabled solutions

One of the key packaged food industry trends is the growing adoption of technology-enabled solutions as they enhance security and convenience. Smart solutions such as embedded NFC and QR codes enable customers and manufacturers to track location, tampering, temperature, quality, and compliance with regulatory standards, among others.

The use of technologies such as AI and big data has also improved automation in procurement. These technologies make it more data driven as they improve demand forecasting, supplier management, and price management. Track and trace solutions help companies to identify supply chain bottlenecks, while AI helps to reduce costs and risks.

Growing demand for transparency and sustainability

A key health food industry trend is the need to collaborate with suppliers that prioritize quality control and testing procedures. Such collaborations are essential to maintain customer trust and to ensure compliance with regulatory standards.

Transparency in the supply chain is gaining prominence as a growing number of consumers are giving importance to production methods and ingredients used. Therefore, letting the consumers know from where the ingredients are sourced, and the production methods will improve their trust. From the supplier’s point of view, by enforcing transparency, drawbacks such as inefficiencies can be detected, and this, in turn, will help improve supply chain efficiency and reduce cost.

Food and Beverages – An Industry Beset with Major Procurement Problems

Supply chain complexity

Supply chain complexity, especially in terms of ensuring safe transport and reducing bottlenecks, is a challenge faced by the industry. Even a small business in the food and beverages industry needs to collaborate with a large number of players. Also, the food and beverages industry requires transportation of food ingredients from far away places in a controlled environment. Therefore, ensuring traceability and tamper-proof, controlled transit is essential to prevent contamination. Meeting this need is not only required to ensure customer trust but also to ensure regulatory compliance.

Geopolitical issues, sanctions, and climate changes have led to a shortage of resources. This, in turn, has driven the demand for local or nearshore sourcing of ingredients.

Labor shortage

The food and beverages industry has always faced labor shortages, and this has only worsened post pandemic. Some of the primary reasons for the industry facing this issue can be long working hours, low wages, and demanding work environment. The industry has a requirement for specialized skilled labor. However, the demand is seasonal, and the competition for recruiting the right candidate is high within the industry. This is because the players in this industry compete from the same talent pool.

Labor shortages will not only increase the cost but can also cause potential disruptions to the supply chain.

Regulatory compliance

With the F&B industry going global, the players have to ensure adherence to not only local regulations but also national and international norms. This is a challenge as the regulations vary and are frequently updated or revised, thus requiring continuous monitoring to ensure compliance.

These regulations lay emphasis on traceability, allergen control, and other quality control measures. Therefore, the players must ensure accurate labeling and packaging requirements. Ensuring labeling and packaging are consumer friendly while providing accurate ingredient lists, nutritional information, allergen declaration, and country of origin can be a challenge, especially when the product is transported to several countries.

Food and Beverage Industry – Pain Points

The food and beverage industry faces several common challenges despite the diverse production processes associated with different food categories. These challenges include managing a time-sensitive supply chain to prevent product spoilage, maintaining a production environment that adheres to strict hygiene and food safety standards, complying with rigorous industry regulations to ensure production practices meet established standards, and navigating the market for price-sensitive products where profit margins are critical.

Procurement Problems in the Food and Beverage Sector

Players in the F&B industry must focus on supplier relationship management, risk mitigation strategies, demand forecasting, and technology adoption such as supply chain visibility tool to streamline their operations, reduce costs, ensure product quality, and improve overall efficiency of the supply chain.

Similarly, the players must keep themselves up breast with the latest updates in the regulatory changes and promote a culture of compliance throughout their operations to avoid penalties, reputational damages, product recalls, or even legal consequences.

To offset labor shortages, players in the F&B industry can invest in outsourcing of functions or incorporating automation, and consider solutions such as offering part-time or flexible work arrangements.

Why Choose SpendEdge?

Ways to improve demand planning

The F&B industry today is highly globalized, i.e., the ingredients are often sourced from far off places. As a result, the players have to deal with ensuring accurate demand forecasting and ensuring optimal conditions are maintained during transit, among others. To overcome these issues, our experts can offer demand planning strategies that aid in improving inventory tracking and real-time updates related to stock.

Cost reduction and cost avoidance

The need to cut costs to improve profit margins have been gaining prominence, especially in the post pandemic era. To achieve this, our team of experts can help you manage and evaluate your suppliers and logistics partners based on their performance and not purely on price. This ensures cost efficiency. We also undertake risk assessments such as analyzing regulatory changes and geopolitical risks to alert our clients about potential threats and offer mitigation strategies, thereby enabling them to cut costs.

Want to know the latest consumer trends, demand patterns, or competitor activities, then contact our experts. They will help you identify the latest in technology or make informed strategic decisions.

Success Story: SpendEdge’s procurement market intelligence reports help category managers in the food and beverage industry optimize their sourcing goals and ensure efficient value delivery

A leading global F&B company needed a partner that could help in ongoing procurement market intelligence and benchmarking support. The support was required specifically for over 50 indirect categories and subcategories such as marketing, MRO, professional services, and T&L.

The company was looking for a partner with domain expertise as well as regional- and country-specific procurement intelligence capabilities. The partner should have the ability to derive granular insights related to the supply market, suppliers, and pricing, among others. The client was also expecting the supplier to assist them with benchmarking information on industry best practices regarding how these categories are managed by best-in-class market players.

We conducted a detailed review of the current category sourcing and procurement strategy as well as an assessment of gaps and opportunities. Based on these, we delivered detailed country-/region-specific insights. The reports were tailor made and used benchmarking analysis to shortlist the right-fit supplier. In addition, our negotiation strategies also helped the client effectively negotiate for the best deal terms with their suppliers.

The Way Ahead in Food and Beverages

The food and beverage industry is a complex and dynamic sector encompassing various production techniques and specialized equipment to transform raw agricultural goods into consumer-ready products. From food processing at food processing plants to packaging in packaging facilities, the industry’s supply chain includes diverse food categories like fresh food, packaged food, and beverages. The integration of advanced food processing equipment and food packaging equipment, along with innovative solutions like edible packaging, ensures safe food handling and sustainability. The industry’s reach extends to numerous retail outlets, reflecting its pivotal role in delivering quality products. By addressing challenges in raw food production, optimizing packaging machines, and maintaining high standards across the agriculture industry, the food and beverage sector continues to meet consumer demands and regulatory requirements effectively.

Author

George Mathew

Associate Vice President, Sourcing and Procurement Intelligence

George is a procurement specialist at Infiniti Research and provides advisory services to clients across the pharmaceutical, CPG & FMCG, energy, and automotive sectors. He specializes in the procurement areas of industry benchmarking, cost modeling, rate card benchmarking, negotiation advisory, and supplier intelligence.