Effective inventory management is critical for the success of any business. Vendor Managed Inventory (VMI) is an approach that has gained traction due to its potential to optimize supply chain efficiency, reduce operational costs, and enhance customer satisfaction.

Understanding Vendor Managed Inventory (VMI)

Vendor Managed Inventory (VMI) is a supply chain initiative where the supplier (vendor) takes responsibility for maintaining the buyer’s inventory levels. This approach involves data sharing between the vendor and the customer (buyer), enabling the vendor to make informed decisions regarding order quantities, replenishment processes, and delivery schedules. By leveraging real-time data sharing, VMI aims to optimize inventory levels, reduce carrying costs, and ensure that the right products are available at the right time.

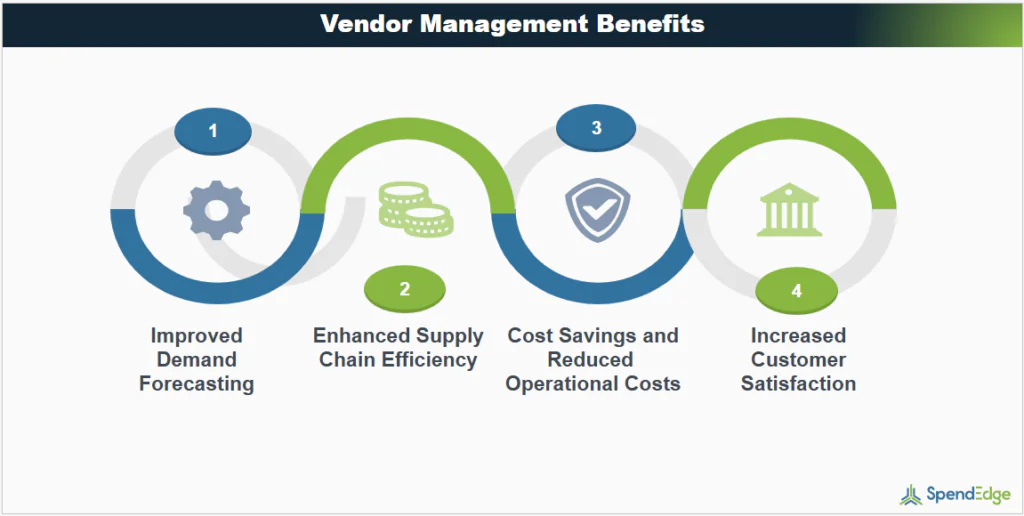

Benefits of Vendor Managed Inventory

Improved Demand Forecasting and Replenishment Processes

One of the primary benefits of VMI is improved demand forecasting. By utilizing historical data, sales patterns, and market trends, vendors can make accurate predictions about future demand. This collaborative forecasting approach allows for more precise production planning and efficient replenishment processes, ensuring that inventory levels are maintained without overstocking or stockouts. For instance, Procter & Gamble (P&G) implemented VMI with Walmart, leveraging historical data and sales patterns to improve demand forecasting. This collaboration led to more efficient replenishment processes and reduced stockouts, significantly enhancing customer satisfaction.

Enhanced Supply Chain Efficiency

VMI enhances supply chain efficiency by streamlining communication channels between vendors and buyers. Automated systems and data analytics tools enable real-time monitoring of inventory levels, allowing for timely replenishment and reducing lead times. This efficiency is further supported by technology solutions such as Inventory Management Systems (IMS) and Electronic Data Interchange (EDI), which facilitate seamless data sharing and inventory visibility. Dell Computers exemplifies this benefit by using VMI to manage its supply chain more effectively. By collaborating with suppliers and using real-time data analytics, Dell reduced lead times and improved inventory visibility, resulting in a more responsive and efficient supply chain.

Cost Savings and Reduced Operational Costs

Implementing VMI can lead to significant cost savings. By optimizing stock levels and reducing overall inventory costs, businesses can free up capital for other strategic initiatives. VMI also reduces operational costs associated with storage, carrying costs, and stock obsolescence. The automated replenishment process minimizes the need for manual intervention, leading to further cost reductions. Johnson & Johnson’s adoption of VMI for its medical devices division is a case in point, as it resulted in reduced storage costs and improved inventory turnover. The automated replenishment system ensured that products were available when needed, leading to substantial cost savings.

Increased Customer Satisfaction

VMI contributes to higher customer satisfaction by ensuring that products are available when needed. By maintaining optimal inventory levels, businesses can meet customer demands more effectively, leading to improved service levels and customer loyalty. The proactive approach to inventory management also helps in addressing market fluctuations and demand fluctuations, ensuring a consistent supply of products. Kimberly-Clark, a global consumer goods company, implemented VMI with key retailers. This initiative led to better inventory management, reduced stockouts, and enhanced customer satisfaction by ensuring that products were always available on retail store shelves.

Risks and Challenges of VMI

Loss of Control and Trust Issues

One of the main risks associated with VMI is the potential loss of control over inventory management. Businesses must place significant trust in their suppliers to manage inventory effectively. This requires strong communication channels, clear performance metrics, and regular performance reviews to ensure that vendors are meeting expectations. For example, a major electronics retailer experienced a temporary loss of control when a key supplier failed to deliver on time, highlighting the importance of trust and robust performance metrics in VMI partnerships.

Data Sharing Concerns

Effective VMI relies heavily on data sharing between vendors and buyers. Concerns related to data security and confidentiality can pose challenges. Businesses must implement robust data sharing protocols and technology solutions to mitigate these risks and ensure the integrity of sensitive information. A pharmaceutical company implemented stringent data sharing protocols and used advanced encryption technologies to ensure the security of sensitive inventory data shared with suppliers, thereby addressing these concerns.

Inventory Management Challenges

While VMI can optimize inventory levels, it also presents challenges related to inventory management. Businesses must closely monitor inventory costs, stock levels, and reorder points to prevent issues such as overstocking or stockouts. Additionally, the integration of VMI software and other technology solutions requires careful planning and execution. A leading automotive parts manufacturer faced challenges integrating VMI software with existing systems. Careful planning and phased implementation helped mitigate these challenges, leading to smoother operations and better inventory control.

Best Practices for Successful VMI Implementation

Establish Strong Strategic Partnerships

Successful VMI implementation requires strong strategic partnerships between vendors and buyers. This involves clear communication, mutual trust, and alignment of goals. Businesses should select suppliers that demonstrate reliability, transparency, and a commitment to continuous improvement. Unilever’s strategic partnership with Tesco focused on clear communication and mutual trust, leading to a successful VMI implementation that improved supply chain efficiency and customer satisfaction.

Utilize Advanced Technology Solutions

Leveraging advanced technology solutions such as Artificial Intelligence (AI), Internet of Things (IoT), and Demand Forecasting Software can enhance the effectiveness of VMI. These tools enable real-time data analysis, automated replenishment, and predictive analytics, providing valuable insights for inventory management. Coca-Cola implemented AI-driven demand forecasting and IoT sensors to monitor inventory levels in vending machines. This advanced technology solution improved inventory management and reduced stockouts.

Focus on Data Analysis and Continuous Improvement

Regular data analysis is crucial for optimizing VMI performance. Businesses should continuously analyze sales patterns, market trends, and inventory data to identify areas for improvement. Implementing a continuous improvement approach helps in refining inventory management strategies and adapting to changing market conditions. A global electronics manufacturer regularly analyzed market trends and sales data to continuously improve its VMI approach, leading to better inventory management and reduced operational costs.

Implement Effective Risk Management Strategies

To mitigate the risks associated with VMI, businesses should implement robust risk management strategies. This includes setting clear key performance indicators (KPIs), conducting regular performance reviews, and establishing contingency plans for unforeseen disruptions. Effective risk management ensures that inventory levels are maintained even in the face of challenges. A major retailer established KPIs and conducted regular performance reviews with suppliers, ensuring that inventory levels were consistently optimized and risks were managed effectively.

Foster Open Communication Channels

Open communication channels between vendors and buyers are essential for the success of VMI. Regular meetings, transparent reporting, and collaborative forecasting sessions help in addressing any issues and aligning strategies. Effective communication fosters a collaborative environment and strengthens the partnership. A leading consumer electronics company held regular meetings with suppliers to discuss performance metrics, align strategies, and address any challenges, leading to a successful VMI implementation.

Future Trends in Vendor Managed Inventory

Integration of AI and IoT

The future of VMI will see increased integration of AI and IoT technologies. AI-powered demand forecasting and automated replenishment systems will further enhance the accuracy of inventory management. IoT devices will provide real-time data on inventory levels, production line status, and retail store shelf conditions, enabling more responsive and efficient supply chain operations. Nestlé is exploring the use of AI and IoT for its VMI initiatives, aiming to improve demand forecasting and real-time inventory management across its global supply chain.

Expansion of VMI in Various Industries

While VMI is commonly used in retail and manufacturing, its adoption is expanding to other industries such as healthcare, automotive, and electronics. The benefits of VMI in improving supply chain efficiency and reducing operational costs are being recognized across diverse sectors, leading to broader implementation. The healthcare industry, for example, is increasingly adopting VMI to manage medical supplies and equipment, ensuring timely availability and reducing overall inventory costs.

Emphasis on Sustainability and Environmental Impact

Future trends in VMI will also focus on sustainability and reducing the environmental impact of supply chain operations. Businesses will seek to optimize transportation routes, reduce waste, and minimize carbon footprints through efficient inventory management practices. Patagonia, a leading outdoor apparel company, is incorporating sustainability into its VMI practices by optimizing transportation routes and reducing waste in its supply chain.

Conclusion

Vendor Managed Inventory (VMI) presents significant opportunities for businesses to enhance supply chain efficiency, reduce costs, and improve customer satisfaction. By leveraging advanced technology solutions, establishing strong strategic partnerships, and focusing on data analysis and continuous improvement, businesses can unlock the full potential of VMI. However, it is essential to address the risks and challenges associated with VMI through effective risk management strategies and open communication channels. As future trends continue to shape the landscape of inventory management, VMI will remain a critical component of successful supply chain strategies