Key takeaways

- The supply chain optimization process involves three key phases: design, planning, and execution, each focusing on different aspects of supply chain operations to achieve seamless integration and efficiency.

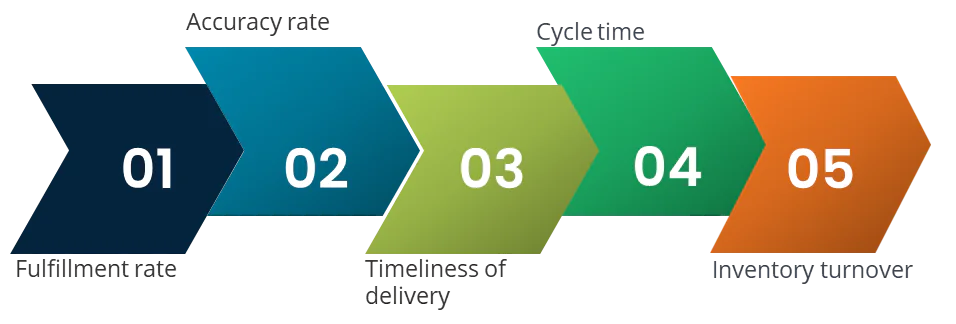

- Tracking KPIs such as fulfillment rate, accuracy rate, timeliness of delivery, cycle time, inventory turnover, and supplier performance provides insights into supply chain performance and facilitates continuous improvement.

- Comprehensive assessment of potential risks and vulnerabilities within the supply chain ecosystem, leveraging advanced analytics and market intelligence to develop proactive risk mitigation strategies and enhance resilience.

- By leveraging SpendEdge’s services, businesses can optimize processes, mitigate risks, capitalize on opportunities, enhance efficiency, and achieve cost savings, thereby gaining a competitive advantage in the market.

In today’s highly competitive business environment, it is essential to optimize the supply chain to maintain a competitive edge. With a strategic approach, it can unlock exceptional efficiency and profitability within value chain operations. Traditional practices are being revolutionized by emerging technologies, while mega trends and evolving customer expectations are further reshaping the landscape.

During this transformation, supply chains have the opportunity to enhance operational effectiveness and embrace emerging digital business models. Adapting to mega-trends is crucial, including the ongoing growth of rural areas globally and the redistribution of wealth to previously underserved regions. Additionally, the need to reduce carbon emissions and comply with traffic regulations for socioeconomic reasons poses significant challenges to logistics. Demographic shifts also present hurdles, with shrinking labor pools and heightened ergonomic demands as the workforce ages.

Have a look at our supply chain intelligence solutions

Supply chain optimization: the Three Phases

Supply Chain Design: Crafting a Strategic Blueprint

The main focus of this first stage is creating a strategic plan for the whole supply chain. It involves forecasting demand and creating the best possible network of distributors, manufacturers, suppliers, and warehouses. Geographical location, transit costs, and capacity restrictions are important factors. Future scalability and flexibility are also essential components of a good supply chain architecture in order to successfully handle market changes or interruptions.

Supply Chain Planning: Orchestrating Tactical Operations

During this stage, the focus shifts to tactical planning to ensure smooth day-to-day operations. Procurement, inventory control, resource distribution, and production scheduling are all included in the tasks. The objectives of supply chain planning are to balance supply and demand, reduce costs, and maximise resource use. Here, it’s critical to make use of cutting-edge technologies and analytics, which offer insightful information for wise decision-making and quick reactions to market dynamics.

Supply Chain Execution: Bringing Plans to Life

The carrying out of predetermined plans is the focus of this phase. The actual transfer of commodities from suppliers to final consumers is included, and it includes order fulfilment, warehousing, shipping, and production. Proactive problem-solving, efficient communication, and real-time tracking are essential. It is important to put in place reliable mechanisms for performance tracking, improved visibility, and goal alignment.

Key Performance Indicators (KPIs) and Metrics for Supply Chain Management

Fulfillment Rate:

The fulfillment rate gauges the percentage of customer orders that are completely fulfilled and delivered on time. It showcases the efficiency and reliability of your supply chain in meeting customer demands promptly, fostering increased customer satisfaction and loyalty.

Accuracy Rate:

The accuracy rate measures the percentage of orders delivered to customers without errors or defects. It encompasses aspects like order precision, timeliness, condition, and documentation. A high accuracy rate signifies a supply chain that consistently delivers orders correctly and completely, leading to enhanced customer satisfaction and reduced costs associated with order errors.

Timeliness of Delivery:

Timeliness of delivery evaluates the percentage of orders delivered within the agreed-upon timeframe. It reflects the dependability of your supply chain in meeting delivery commitments and customer expectations. High rates of on-time delivery enhance customer satisfaction, build trust, and fortify customer relationships.

Cycle Time:

Cycle time denotes the total duration required for a product or service to traverse the entire supply chain, from order placement to delivery. It encompasses processing, production, transportation, and other fulfillment activities. Monitoring cycle time aids in identifying bottlenecks, streamlining processes, and enhancing overall efficiency.

Inventory Turnover:

Inventory turnover measures how swiftly inventory is utilized or sold within a specific timeframe. It showcases the effectiveness of inventory management and demand forecasting processes. A high inventory turnover rate indicates efficient inventory utilization, reduced carrying costs, and improved cash flow.

Inventory Holding Period:

Inventory holding period quantifies the average number of days required to sell or consume inventory. It provides insights into inventory management efficiency and aids in determining optimal inventory levels to meet customer demand while minimizing carrying costs.

Cash-to-Cash Cycle Time:

Cash-to-cash cycle time (C2C) measures the duration for cash invested in the supply chain to be converted back into cash through sales. It encompasses payment to suppliers, inventory conversion to sales, and customer payment collection. A shorter C2C cycle time signifies effective cash flow management and enhanced working capital efficiency.

Supplier Performance:

Supplier performance assesses the reliability and quality of suppliers in delivering products or materials meeting required standards and specifications. It evaluates factors such as product quality, compliance, and adherence to delivery schedules. High supplier performance ensures supply chain resilience, reduces rework costs, and enhances customer satisfaction.

Supplier Lead Time:

Supplier lead time quantifies the time taken for suppliers to deliver ordered products or materials. It encompasses the duration from order placement to arrival at your facility. Managing and monitoring supplier lead time is critical for maintaining a responsive supply chain, meeting customer demand, and minimizing disruptions caused by supply delays.

Freight Cost per Unit Shipped:

Freight cost per unit shipped measures the average transportation cost for shipping a single unit of product from your facility to the customer. It includes shipping fees, fuel costs, handling charges, and surcharges. Monitoring this metric aids in assessing transportation efficiency, identifying cost-saving opportunities, and optimizing logistics operations.

How can SpendEdge help businesses with supply chain optimization

Supply Chain Mapping:

We carefully map all the complexities of your supply chain network as part of our supply chain mapping solution. We offer in-depth graphic depictions of the money, information, and items moving through your supply chain ecosystem. We assist you in gaining a comprehensive understanding of your supply chain, which enables well-informed decision-making and strategic planning, by identifying important stakeholders, dependencies, and vital nodes. With our experience, you can reduce risks, streamline procedures, and take advantage of chances to increase productivity and cut expenses.

Supply Chain Updates:

In today’s fast-paced business environment, it is crucial to keep up with the latest supply chain advancements. Our supply chain updates service offers real-time insights and analysis on industry trends, market dynamics, regulatory changes, and emerging technologies that impact your supply chain. We provide timely updates tailored to your specific industry and business requirements, enabling you to adapt quickly to changing circumstances, seize opportunities, and minimize risks. With our proactive approach to disseminating information, you can optimize your supply chain strategies and stay ahead of the competition.

Supply Chain Risk Analysis:

Managing risks in your supply chain is crucial for maintaining your business continuity and reputation. Our supply chain risk analysis service offers a comprehensive assessment of potential risks and vulnerabilities within your supply chain ecosystem. We use advanced analytics, industry expertise, and market intelligence to identify, evaluate, and prioritize risks across various dimensions such as geopolitical, economic, environmental, and operational factors. By quantifying risks and their potential impacts, we help you develop proactive risk mitigation strategies, build resilience, and protect your business from disruptions. With our tailored risk management solutions, you can navigate uncertainties with confidence and optimize your supply chain performance.

Conclusion

Supply chain optimization is no longer just about efficiency. It is now a strategic imperative that businesses must prioritize to maintain a competitive edge. To achieve this, meticulous supply chain mapping, timely updates, and thorough risk analysis are essential. By doing so, businesses can unlock opportunities for efficiency gains, cost savings, and resilience. SpendEdge provides a comprehensive suite of services that enable organizations to gain valuable insights, mitigate risks, and capitalize on emerging trends to drive operational excellence and sustainable growth. By embracing a proactive approach to supply chain management, businesses can navigate complexities with confidence, adapt to evolving market dynamics, and position themselves for success in the ever-changing landscape of global commerce.

For more information