By: George Mathew

Why investments in logistics risk management almost always make sense

Financial instability in a sub-tier supplier network can cause enough drama and jeopardy for a business by hitting operations and profitability. Working with a vendor with suboptimal financial planning is certain to have a knock-on effect on a downstream enterprise by way of poor quality products or input materials as well as supply squeezes and breakdowns, leading to higher prices in the hands of customers and item shortages. Both these developments are going to stir consternation among shoppers. With supply chains turned upside down and logistics squeezed, there could be slippages in meeting regulatory mandates, and this is serious! Penalties for non-compliance can put enterprises back by millions of dollars, hammering bottom lines and fiscal stability. Believe it or not, average fines could be as high as $150 million, depending on the severity of the transgression. Besides the financial risks outlined above, if you are in business, there is no escaping strategic and physical risks. Certainly, there are ways to mitigate their impact. Left unattended, strategic risks could engulf an entire swathe of activities like commercial motor vehicles management and legal procedures, apart from unforeseen “Act of God” events. So, forget about taking your focus away from risk management in logistics and supply chain. There are umpteen other types of risks like operational issues, economic uncertainties, geopolitical instability, and labor shortages. Time and space constraints curtail their detailed discussion here. Suffice to say, all of these risks need to be tacked with finesse without affording them a chance to dilute or harm the monetary worth of your brand.

Importance of the Service

Supply chain mapping tool

Businesses now have access to an expanding inventory of tools, some of them with AI-powered architecture, to significantly ease risk management in logistics and supply chain. Let’s discuss. Key among these tools is the supply chain mapping solution, which captures data from across participants in an organization’s supply networks, covering individuals and businesses. The information, thus captured, is then used to generate real-time maps of the business’s global supply network. As a result, organizations have started “seeing” their supply networks for the first time with remarkable clarity and, further, perceiving the “deeper connections” therein. With improved visibility, businesses are finding new ways to decongest the supply chain and improve the workflows while keeping supply-side risks under control.

Geopolitical risk analysis tool

Some of these platforms provide hourly updates on nearly two score political risks from 100+ countries and their potential impact on business, industry, global trade, and, most importantly, supply lines. Backed by AI/ML algorithms and human experts in government and politics, these systems are reportedly capable of foretelling geopolitical risks within and across nations with high accuracy. By doing so, geopolitical risk management tools help organizations deal with uncertainties more confidently and identify favorable market circumstances for the longer term. The tool has brought renewed attention to risk management in logistics and supply chain. Large businesses, insurers, and the asset management industry, besides governments, have evinced keen interest in this technology, which, by all indications, is poised for a breakout.

Vendor risk management tool

In general, these tools deliver a continuous stream of powerful vendor performance metrics, so businesses can make better, faster, and more timely decisions to defuse risks. Essentially, these solutions eliminate human intervention and the risk of cognitive errors that often seep into the vendor management process. With this tool in place, organizations can take a consistent and methodical approach to risk management in logistics and supply chain. It is already enabling organizations to precisely identify, evaluate, and, further, tone down risks associated with their supply chain participants.

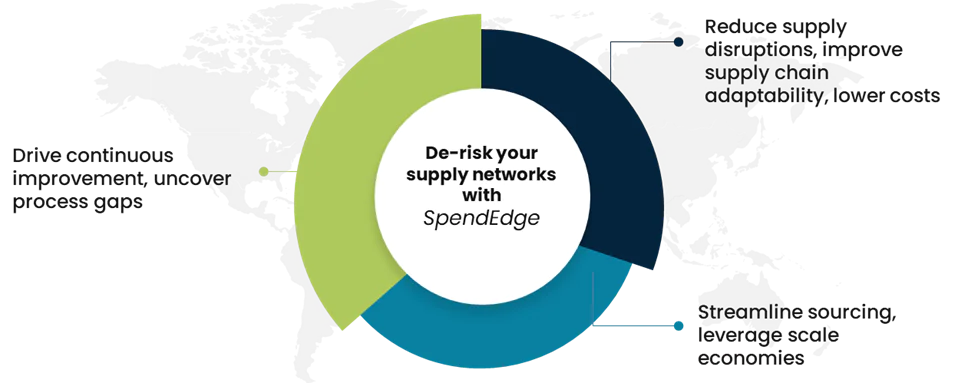

How SpendEdge can help you

Procurement experts at SpendEdge enable businesses of all sizes to make better purchase decisions based on data-based insights. Our guidance and recommendations help C-suiters stay updated on the latest trends in the business logistics landscape. Our expert teams are committed to monitoring supply-side developments such as supplier capabilities, supply network disruptions, regulatory changes, and various market shifts that could potentially impact logistics networks. Our experts have more than two decades of experience in building highly efficient sourcing networks that are faster and simpler than competing ones and cover several critical aspects in sourcing. These include developing supply channels, vendor selection, contract negotiation, and cost management. Our trusted team of advisors collaborates with clients’ procurement organizations to surface potential risks and assess their impact, apart from the probability of things going wrong by any chance. We also direct our efforts to keep risks down to a bare minimum where they cannot be eliminated entirely.

D-Risk, a homegrown SpendEdge innovation, is already proving to be an invaluable tool for businesses keen on sizing up risks and taking proactive steps to contain them. Our procurement experts bring this tool into play to help enterprises take stock of and alleviate potential supplier risks. This involves factoring in internal and external supply-side developments, geopolitical influences, cost structures, as well as reputational risks.

SpendEdge success story: How a North American CPG enhanced supply chain “bounce-back capabilities”

Material costs for CPGs have jumped by more than a third since 2020, and supply disruptions are to blame for the most part. Cost increases invariably lead to upward revision of prices in the industry, and consumers are unlikely to take cost pass-throughs lightly. Supply squeezes and the shortages they give rise to might prompt consumers to prioritize a more readily available brand over another. The supply-side dynamic is not as scary as that in our client’s case. Even so, the company, a North American CPG, was still grappling with some supply chain interruptions from time to time. Easing risk management in logistics and supply chain was important to the client. The CPO realized the potential risk it posed to business operations and, importantly, profitability. Before things could take a turn for the worse, our client reached out to us for assistance in alleviating the supply chain woes. Bolstering the supply chain’s resilience, so it can bounce back and respond to operational disruptions, was particularly significant in the client’s scenario.

Our experts pored over data from across the length and breadth of the client’s supply chain using the most contemporary tools of the trade. Risk management in logistics and supply chain has always been a big part of what we do in market intelligence. In this case, we paid a great deal of attention to past and current market data for the CPG sector. Most important of all, we ensured critical data on worldwide political instability, armed conflicts, and various geographical events came into picture. This is where our proprietary risk analysis tool came in handy by serving up highly relevant data on labor issues, workforce health and wellbeing, as well as sustainability due diligence at tier-1 supplier organizations. For context, our tool uses tens of thousands of data points from fair and unbiased sources. Supplier concentration was identified as a key issue requiring immediate redressal.

Now that we had all the relevant supplier metrics at our fingertips, it was time to get into action mode. Without losing any time, our team proceeded to roll out a supplier onboarding process to bring in new vendors and broaden the client’s vendor base to reduce the concentration risk arising from overreliance on a few key suppliers. To ensure real-time information transmission and receipt in times of disruption, our experts recommended that the client implement robust protocols and embrace industry-leading practices. Detailed plans were also created to guide the client’s journey toward process improvement, technology upgrades, and logistics energization. With our custom approach to risk management in logistics and supply chain, the client succeeded in improving the capability of its supply networks to withstand and bounce back from unforeseen disruptions.