Optimisation of supply chain data has become imperative for organisations aiming to maintain competitiveness and ensure operational efficiency. The effective management and utilization of data within the supply chain can significantly impact various aspects of a business, including cost reduction, improved decision-making, enhanced customer satisfaction, and streamlined operations. This essay delves into the importance of optimizing supply chain data and explores strategies for mastering its flow to achieve sustainable success.

The Significance of Supply Chain Data Optimisation

Enhanced Visibility

A multinational electronics manufacturer with a complex supply chain network that spans multiple continents can benefit from supply chain data analytics tools like RFID tracking and real-time inventory management systems. With these tools, the company can gain comprehensive visibility into the movement of raw materials, work-in-progress, and finished goods across its global operations. This enhanced visibility enables proactive decision-making, allowing the company to anticipate potential disruptions, optimize inventory levels, and ensure timely delivery to customers.

Improved Efficiency

A prominent e-commerce retailer is facing the challenge of managing an ever-growing product catalogue while ensuring high levels of customer satisfaction. To tackle this issue, the retailer has implemented advanced data analytics and automation technologies to optimize its supply chain processes, right from order fulfilment to last-mile delivery. By using predictive analytics to anticipate demand patterns and automating order routing and fulfilment operations, the retailer is able to minimize order processing times, reduce shipping costs, and improve overall operational efficiency. This, in turn, results in enhanced customer experiences and increased profitability.

Demand Forecasting Accuracy

Accurate demand forecasting is crucial in the fast-moving consumer goods (FMCG) industry to avoid stockouts and minimize excess inventory holding costs. A global food and beverage company utilizes advanced data analytics techniques, including machine learning algorithms and predictive modeling, to analyze vast volumes of historical sales data, market trends, and external factors such as weather patterns and promotional activities. By refining its demand forecasting models based on these insights, the company achieves a higher level of accuracy in predicting consumer demand, enabling it to optimize inventory levels, reduce stockouts, and improve supply chain efficiency while meeting customer expectations.

Enhanced Collaboration

Promoting innovation, cutting costs, and enhancing overall supply chain performance all depend on cooperation amongst supply chain participants. A large car manufacturer works closely with its network of suppliers, component producers, and logistics partners to reduce lead times, maximise production schedule, and guarantee components arrive at assembly facilities on time. The manufacturer and its partners can identify possible bottlenecks, optimise production workflows, and implement continuous improvement initiatives by exchanging real-time production data, inventory levels, and delivery schedules through a centralised supply chain platform. This will ultimately improve collaboration and drive operational excellence throughout the entire supply chain network.

Strategies for Optimising Supply Chain Data

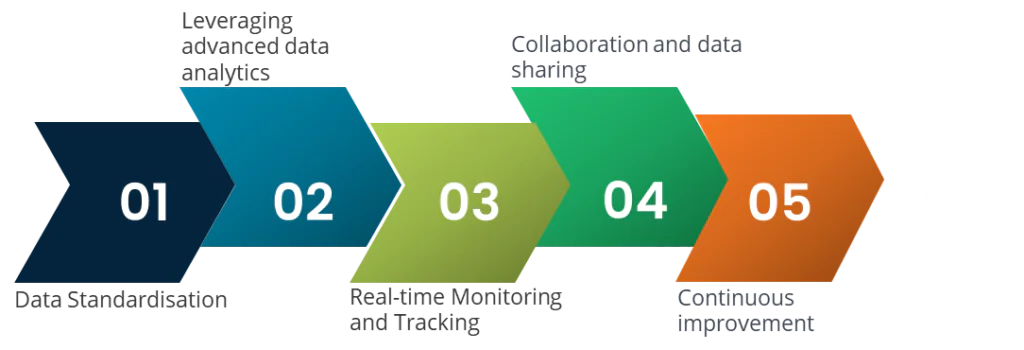

To master the flow of supply chain data and harness its full potential, organizations can implement the following strategies:

Data Standardization

It is important to use consistent data formats, protocols, and terminology in the supply chain ecosystem to ensure smooth integration and interoperability. To achieve efficient data sharing and communication between different systems, it is recommended to adopt industry-standard data exchange protocols, such as Electronic Data Interchange (EDI) or Application Programming Interfaces (APIs).

Leveraging Advanced Analytics

Embracing advanced analytics techniques such as predictive modeling, machine learning, and artificial intelligence empowers organizations to extract actionable insights from vast volumes of supply chain data. These analytical tools enable proactive risk management, demand forecasting, and optimization of inventory levels based on changing market dynamics and customer preferences.

Real-time Monitoring and Tracking

Implementing IoT-enabled sensors, RFID tags, and GPS tracking systems allows organizations to monitor the movement of goods in real-time throughout the supply chain. This real-time visibility enables proactive issue detection, exception management, and timely intervention to prevent disruptions or delays.

Collaboration and Data Sharing

Establishing collaborative partnerships with suppliers, logistics providers, and other stakeholders facilitates data sharing and exchange of information across the entire supply chain network. Cloud-based platforms and collaborative tools enable secure sharing of data in real time, fostering transparency, agility, and trust among partners.

Continuous Improvement

Adopting a culture of continuous improvement and data-driven decision-making is essential for optimizing supply chain performance. Regular performance reviews, root cause analysis, and feedback loops enable organizations to identify inefficiencies, implement corrective actions, and drive incremental enhancements in supply chain processes.

Conclusion

Optimizing supply chain data is of utmost importance for organizations aiming to succeed in today’s competitive business environment. By managing the flow of data and implementing strategic initiatives to maximize its potential, businesses can benefit from increased visibility, enhanced efficiency, accurate demand forecasting, and seamless collaboration across the supply chain network. By continuously innovating and committing to data-driven decision-making, organizations can achieve sustainable success and maintain a competitive edge in the dynamic global marketplace. In conclusion, optimizing supply chain data can help businesses thrive and succeed in the long run.