By: George Mathew

Data quality in procurement is crucial for informed decision-making, cost control, supplier management, and risk mitigation, ensuring efficient and effective procurement processes. Data quality refers to the accuracy, completeness, consistency, and reliability of data. High-quality data is free from errors, duplicates, and inconsistencies, making it suitable for reliable analysis, decision-making, and reporting. It is essential in various fields, such as business, research, and healthcare, to ensure reliable and meaningful outcomes.

Additionally, inaccurate data can lead to miscalculations of inventory levels, which may result in overstocking or stockouts, further affecting costs and customer satisfaction. It can also hinder spend analysis and strategic decision-making, leading to missed savings opportunities and reduced overall procurement performance. Addressing these issues requires a comprehensive data quality management strategy and ongoing data validation processes.

Strategies to address data quality and integration challenges to achieve transparent visibility in procurement

Data requirements and standards: how it is collected, stored, and shared

Defining data requirements and standards involves establishing clear guidelines on how data should be collected, stored, and shared within an organization. This includes specifying data formats, storage methods, access controls, and adherence to industry standards and protocols. This trend aims to ensure data consistency, integrity, and compliance, ultimately enhancing data quality and facilitating efficient data utilization. It helps organizations make informed decisions, streamline processes, and adapt to evolving data privacy and regulatory requirements.

Choosing the appropriate data tools and leveraging existing data tools efficiently:

Using appropriate data sources and tools entails selecting the right data tools and maximizing the efficiency of existing ones. It involves identifying data sources that best align with an organization’s objectives, ensuring data accuracy, and optimizing data storage, retrieval, and analysis tools. Organizations can harness data effectively by making informed choices and enhancing decision-making, business intelligence, and competitiveness. It also allows them to adapt to evolving data technologies and gain a competitive edge by capitalizing on their data assets.

Implement data quality checks and improvements:

Implementing data quality checks and improvements focuses on maintaining data accuracy, completeness, timeliness, and consistency. It involves establishing processes and technologies that validate, cleanse, and enhance data continuously. By doing so, organizations can rely on high-quality data for informed decision-making, compliance with regulations, and improved operational efficiency. This trend is critical in an era of data-driven insights, where unreliable or inconsistent data can lead to flawed analyses and decisions, potentially harming an organization’s competitiveness and reputation.

Enabling data integration: Connecting and sharing the data among different systems

Enabling data integration and collaboration involves seamlessly connecting and sharing data across diverse systems, platforms, and stakeholders, often employing common data formats, standards, and protocols. This approach breaks down data silos, fostering collaboration, and facilitating a holistic view of information. It enhances data accessibility, efficiency, and decision-making capabilities while promoting interoperability among applications and departments. Embracing data integration and collaboration empowers organizations to harness the full potential of their data, streamline operations, and adapt to the demands of a rapidly evolving digital landscape.

Improved data quality and integration in the supply chain:

Achieving supply chain visibility and benefits focuses on enhancing data quality and integration throughout the supply chain. By implementing robust data management practices and integrating systems, organizations gain real-time insights into their supply chain operations. This results in improved decision-making, reduced operational costs, better inventory management, and increased responsiveness to market fluctuations. Supply chain visibility enables businesses to optimize processes, enhance customer satisfaction, and adapt to unforeseen challenges, ultimately ensuring more efficient and competitive supply chain management.

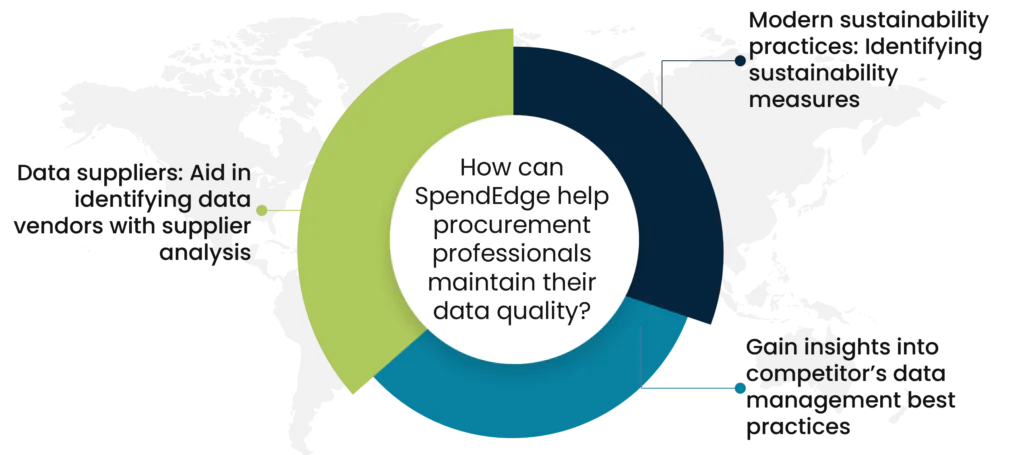

How can SpendEdge help procurement professionals maintain their data quality?

Data suppliers: Aid in identifying data vendors with supplier analysis

At SpendEdge, we use a sophisticated methodology to select the best suppliers available in the market. We go beyond traditional filters like revenue, performance, and service quality to identify the most suitable data dealers. Our team of experts uses advanced statistical and modeling techniques, along with curated data sets, to evaluate the capabilities of suppliers. We sort the suppliers into different quadrants based on their operational and functional capabilities and then rank them to identify the best-fit suppliers. Additionally, we provide additional information on the most suitable suppliers for engagement.

Gain insights into competitor’s data management best practices:

SpendEdge offers valuable support in gaining insights into competitors’ data management best practices. They conduct thorough market research to analyze and document how competitors handle data. Furthermore, they provide benchmarking services that allow businesses to compare their data management strategies with industry peers, highlighting areas for improvement and providing recommendations based on the observed best practices of competitors. This information empowers organizations to enhance their data management processes and stay competitive in their respective markets.

Modern sustainability practices: Identifying sustainability measures

By utilizing our expert intelligence, you can easily identify sustainable practices that are being adopted globally and in specific geographies related to your company’s operations. Our services enable you to evaluate the strategies of suppliers in your network and identify any existing or potential sustainability gaps. We help you assess the social and environmental risk factors of each supplier, monitor compliance challenges within the supply chain, and provide relevant insights to guide you toward a sustainable future for your organization and society.

Success story: Here’s how SpendEdge helped an automobile company with data procurement

Our client is an automobile company based in the US that specializes in the manufacturing of a variety of vehicles, such as cars, SUVs, hybrids, vans, and trucks. They rely on procurement data to make important business decisions. However, recently, the client has been facing significant challenges in ensuring the quality of their procurement data. Inaccurate supplier information, inconsistent records, and a lack of a centralized data management system have hindered their decision-making capabilities and impacted their relationships with suppliers.

Our specialist advisors at SpendEdge conducted an in-depth audit of existing data to identify inaccuracies and inconsistencies, deployed a centralized procurement management system that allowed real-time updates and data synchronization, and utilized advanced analytics tools to identify innovative suppliers in the data management solutions domain. Additionally, conducted a benchmarking analysis to compare the client’s data management practices with industry competitors, conducted market research to identify emerging trends and technologies in data management within the automobile industry, and implemented continuous monitoring mechanisms to ensure data quality was maintained over time.

Our solutions helped the client to successfully overcome data quality challenges in procurement by implementing a robust data management system, fostering collaboration with innovative suppliers, and continuously monitoring and improving their data quality practices. These efforts not only improved internal processes but also strengthened their position in the highly competitive automobile industry.

Contact us now to solve your procurement problems!

Author’s Details

George Mathew

Associate Vice President, Sourcing and Procurement Intelligence

George is a procurement specialist at Infiniti Research and provides advisory services to clients across the pharmaceutical, CPG & FMCG, energy, and automotive sectors. He specializes in the procurement areas of industry benchmarking, cost modeling, rate card benchmarking, negotiation advisory, and supplier intelligence.