Calculating and understanding the Cost of Goods Sold (COGS) is essential for businesses. COGS refers to all expenses incurred by a business in producing or purchasing the goods it sells during an accounting period. These expenses include direct costs like materials, labor, and overhead, as well as indirect costs such as shipping and freight charges, inspection and quality control expenses, import duties, storage and warehousing expenses, supplier-related expenses, and financing inventory charges.

While business owners typically consider only the direct expenses that are incurred to produce and deliver a product, there are also hidden costs that can significantly impact COGS. These costs are often overlooked, but they can arise from various sources, such as unexpected maintenance fees, storage costs, legal fees, and supply chain disruptions. Hidden costs can have a significant impact on a company’s bottom line and overall profitability. Therefore, it’s essential for businesses to carefully evaluate all costs associated with their operations to accurately calculate their COGS and ensure long-term profitability.

What is the impact of procurement on the Cost of Goods Sold(COGS)

Supplier Selection and Negotiation:

Supplier selection and negotiation have a significant impact on a business’s Cost of Goods Sold (COGS). Effective supplier selection enables a company to identify reliable partners that offer competitive pricing and high-quality materials or products. Negotiating favorable terms and pricing agreements with these suppliers can result in cost savings, reducing the purchase cost of goods. Furthermore, strong negotiation skills can lead to volume discounts and other cost-cutting concessions. Overall, smart supplier selection and skillful negotiation not only lower direct procurement costs but also enhance a company’s ability to maintain or improve product quality, ultimately reducing COGS and positively impacting profitability.

Supplier Relationships: Building strong, long-term relationships

Building strong, long-term supplier relationships can have a profound impact on a business’s Cost of Goods Sold (COGS). A close and enduring collaboration with suppliers often leads to improved communication, trust, and mutual understanding. This can result in more favorable terms, consistent pricing, and priority access to resources, helping to stabilize and even reduce procurement costs. Additionally, long-term relationships tend to lead to more flexibility in addressing supply chain challenges, risk management, and shared cost reduction initiatives. These benefits can translate into cost savings and efficiency gains, ultimately contributing to lower COGS, which positively impacts a company’s bottom line and competitiveness.

Quality Control and Efficiency:

Quality control and efficiency measures can significantly impact a business’s Cost of Goods Sold (COGS). Rigorous quality control procedures ensure that defective or substandard materials do not enter the production process, reducing waste and rework costs. Moreover, efficient supply chain and production processes lead to reduced labor and overhead expenses. Streamlined operations, automation, and optimized workflows can enhance productivity and minimize resource utilization. These improvements in quality control and efficiency not only lower the direct cost of producing goods but also lead to higher production yields and fewer disruptions, which in turn result in lower COGS.

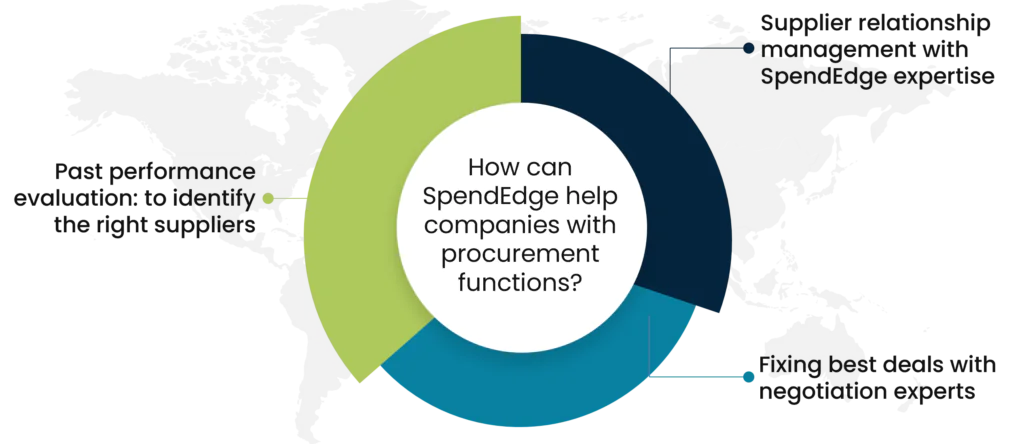

How can SpendEdge help companies with procurement functions?

Past performance evaluation: to identify the right suppliers:

At SpendEdge our experts aid in past performance evaluation to identify the right suppliers by leveraging their expertise and data analytics. We analyze historical supplier performance data, assessing factors such as on-time delivery, product quality, and adherence to contract terms. This evaluation provides an objective view of a supplier’s track record. Our experts also conduct comprehensive risk assessments, ensuring that potential suppliers are financially stable and have a history of ethical business practices. With this information, businesses can make informed decisions, choosing suppliers with a proven track record of reliability and quality, which reduces supply chain disruptions and enhances overall procurement efficiency.

Supplier relationship management with SpendEdge expertise:

SpendEdge specializes in Supplier Relationship Management (SRM), focusing on the development and maintenance of strategic and mutually beneficial supplier relationships. Our experts excel in supplier selection, leveraging their expertise to identify the most suitable suppliers through rigorous evaluations. We establish key performance indicators to track and measure supplier performance, ensuring contractual compliance and quality standards. We also provide risk mitigation strategies to address potential supply chain disruptions and foster collaboration between businesses and their suppliers to drive innovation, cost reduction, and process improvement. Our SRM expertise is geared towards optimizing supplier relationships, resulting in cost savings, quality enhancements, and improved supply chain efficiency.

Fixing best deals with negotiation experts:

Our experts can assist in securing the best deals through negotiation expertise by deploying skilled professionals who excel in the art of supplier negotiations. We have deep market knowledge and insights, enabling them to identify cost-saving opportunities and value-added benefits. We engage in collaborative negotiations with suppliers to secure favorable terms, including competitive pricing, volume discounts, and flexible contract terms. Our negotiation specialists leverage their experience to ensure that businesses get the most advantageous deals, resulting in cost reduction and improved supplier relationships. With our guidance, companies can achieve significant savings and enhance their overall procurement efficiency

The success story of SpendEdge helping a pharmaceutical company

A prominent global pharmaceutical company headquartered in France was on a mission to optimize its sourcing costs, specifically targeting capital expenses related to building management. They partnered with our SpendEdge experts.

At SpendEdge our team of experts conducted a thorough benchmarking analysis within the pharmaceutical industry, uncovering best practices adopted by their peers. We took a step further by considering regional nuances and providing a comprehensive strategy for their client. Armed with this knowledge, the pharmaceutical company successfully revamped its procurement function within the category, aligning it with best practices from multiple industry peers. This strategic transformation led to significant cost reduction and enhanced efficiency, showcasing our expertise in driving procurement excellence.