Supply chain visibility is the capability to track inventory movement throughout the supply chain. Real-time supply chain visibility offers a comprehensive view of a company’s logistics, inventory, and warehouse management processes in real time. Advanced AI-driven platforms provide total visibility into shipments and inventory, from air freight to warehouse bin levels. This visibility allows shippers to enhance customer service, cost controls, and risk mitigation by managing inventory in transit, providing proactive status updates, and limiting disruptions. The goal is to gain insights into supply chain operations while reducing risk, optimizing efficiency, and making data-driven decisions. Supply chain visibility benefits include improved coordination, risk mitigation, and accountability, ultimately leading to agile and resilient supply chains.

Supply chains have historically been constructed with a focus on logistics, with efforts concentrated on analyzing the movement of goods as they enter and exit factories or warehouses. However, the advent of digital supply chain networks has brought about a significant shift in the industry. As supply chains expand and become more extensive, the need for visibility becomes more crucial. This can significantly reduce disruptions, prevent late deliveries, and improve overall workflow.

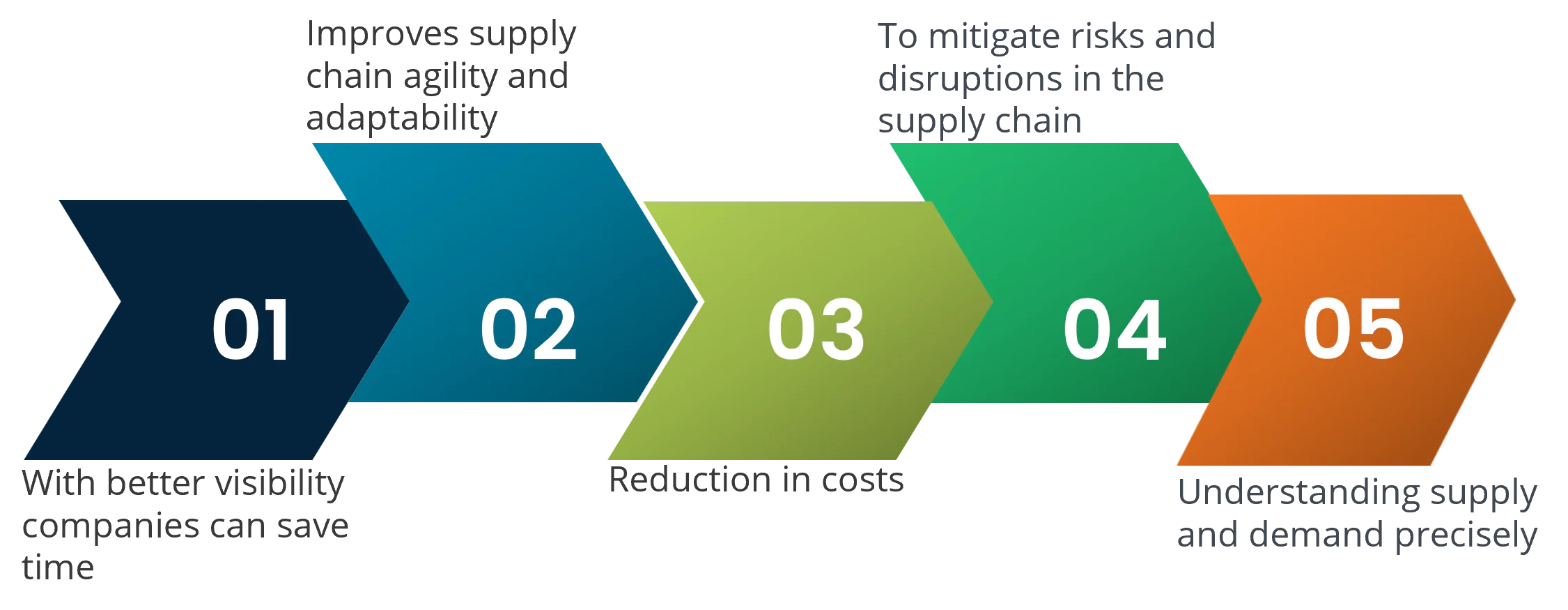

Here are the advantages of visibility into supply chain activities

With better visibility companies can save time:

Automating the tracking process across all transportation parties saves time by streamlining data collection and analysis. With enhanced supply chain visibility, companies can proactively identify real-time inefficiencies, delays, or disruptions. This enables prompt decision-making and the ability to mitigate risks, reducing overall lead times and improving customer satisfaction. Additionally, the automated system facilitates seamless communication between stakeholders, fostering collaboration and transparency throughout the supply chain network, ultimately optimizing operations and driving cost savings.

Improves supply chain agility and adaptability:

Enhancing supply chain visibility improves agility and adaptability by providing real-time insights into inventory levels, demand fluctuations, and supplier performance. With this visibility, companies can quickly adjust production schedules, inventory levels, and distribution strategies to meet changing market demands or unforeseen disruptions. By proactively identifying potential bottlenecks or risks, businesses can implement agile responses, such as alternative sourcing or transportation routes, ensuring uninterrupted operations and maintaining customer satisfaction. Ultimately, this increased agility enables businesses to stay competitive in dynamic market environments and effectively respond to evolving customer needs.

Reduction in costs:

Improved supply chain visibility leads to reduced costs associated with delays and chargebacks by enabling proactive identification and mitigation of potential issues. With real-time tracking and monitoring across all transportation parties, businesses can anticipate delays or discrepancies in shipments and take corrective actions promptly. By minimizing delays and errors, companies can avoid costly chargebacks and penalties while also optimizing resource utilization and operational efficiency. This ultimately results in lower overall transportation and inventory holding costs, enhancing profitability and competitiveness in the market.

To mitigate risks and disruptions in the supply chain:

Enhanced supply chain visibility enables businesses to mitigate disruptions and manage risk effectively. By continuously monitoring all aspects of the supply chain, including inventory levels, supplier performance, and transportation statuses, companies can quickly identify potential disruptions such as natural disasters, supplier failures, or transportation delays. With this foresight, businesses can implement contingency plans, such as alternative sourcing or distribution channels, to minimize the impact of disruptions and ensure continuity of operations. Ultimately, this proactive risk management approach enhances resilience.

Understanding supply and demand precisely:

Supply chain visibility provides a precise understanding of supply and demand by tracking inventory levels, production rates, and consumer buying patterns in real-time. With this comprehensive data, businesses can accurately forecast demand, optimize inventory levels, and adjust production schedules accordingly. By aligning supply with demand, companies can prevent stockouts or overstock situations, reduce excess inventory holding costs, and improve overall operational efficiency. This precise understanding enables businesses to meet customer demands effectively, enhance satisfaction, and capitalize on market opportunities while minimizing waste and improving profitability.

Effective solutions to enhance supply chain visibility

Digital supply chain model:

A robust digital supply chain model enhances supply chain visibility by integrating data from various sources across the supply chain network. Utilizing technologies like IoT sensors, RFID tags, and advanced analytics, it captures real-time data on inventory levels, production processes, transportation statuses, and customer demand. This centralized data repository enables stakeholders to access accurate and up-to-date information, facilitating proactive decision-making and risk management. Additionally, digital supply chain models often incorporate predictive analytics and AI algorithms, enabling predictive insights into future trends and potential disruptions. Overall, a good digital supply chain model enhances transparency, agility, and efficiency, driving improved supply chain visibility and performance.

Intelligent supply chain visibility:

Intelligent supply chain visibility is a combination of structural and dynamic visibility, supported by analytical techniques and artificial intelligence. Each type of visibility has its own characteristics and benefits.

Structural visibility:

Structural visibility allows companies to obtain a snapshot of their operations, revealing crucial insights such as supplier locations, manufacturing points, logistics routes, and interrelationships within the supply chain network. By understanding these aspects, businesses can uncover hidden issues, identify potential risks, and recognize weaknesses in their supply chain. This comprehensive view enables proactive risk mitigation, optimization of logistics routes, and strengthening of relationships with partners. Ultimately, structural visibility empowers companies to enhance efficiency, resilience, and strategic decision-making within their supply chain operations.

Dynamic visibility:

Dynamic visibility enables companies to monitor and respond to events in real-time, offering a progressive enhancement of capabilities. This includes tracking product locations throughout the supply chain, monitoring the operational performance of plants and warehouses, identifying disruptions as they occur, and understanding their impact. By swiftly recognizing and responding to disruptions, businesses can minimize their effects on operations and customer service. This real-time insight empowers proactive decision-making, optimizing resource allocation, and enhancing overall supply chain resilience and responsiveness.

Success Story

A leading heavy equipment manufacturer recognized this challenge and sought the expertise of SpendEdge to fortify their supply chain strategy. The client’s heavy equipment manufacturing operations were heavily dependent on a specific raw material, leaving them vulnerable to potential supply disruptions. We conducted a thorough analysis of the client’s supply chain, leveraging advanced methodologies to map all nodes and potential risk parameters. By delving deep into supplier networks, transportation routes, and geopolitical factors, our professionals provided actionable insights to enhance supply chain resilience. Our comprehensive supply chain mapping enabled the client to gain a holistic view of their raw material sourcing process. Armed with this knowledge, the client implemented a dual-sourcing strategy, diversifying their supplier base and mitigating supply risks. This proactive approach not only safeguarded against potential disruptions but also optimized procurement costs and improved overall supply chain efficiency.