By: Ankur Rishi

To navigate markets in times of tumultuous change and emerge unscathed, every CPO needs a medium-to-long-term procurement strategy to optimize cost and manage all resources more effectively. Without taking a step back, one can’t hope to gain the perspective needed to translate high-level procurement thinking to concrete on-the-ground action. A carefully considered and planned procurement strategyconnects sourcing precepts with everyday practice. Successful sourcing strategies wrap around two key factors germane to the procurement function, namely, risk and profitability. Containing risks without giving them a chance to gut the enterprise is a key responsibility of procurement. Purchasing more than the “right quantity of goods,” leading to excess inventory on hand, is a key risk in procurement. The polar opposite of this is carrying insufficient stock, which cannot keep pace with customer orders, resulting in stockouts! Inaccurate inventory data and faulty demand forecasting are to blame for the most part for both these equally unwelcome scenarios. Business margins take a direct hit in both cases due to loss of revenue and wasted storage space. Likewise, cost-efficiency, all-too-often taken for granted in the procurement function, ought to be an important plank of any procurement strategy worth its name.

Risk mitigation should be a priority in these times of flux

By the way, overstocking and stockouts are not the only risks procurement strategy professionals are strung up about. The absence of a centralized vendor management channel means procurement organizations will end up making ad hoc payments (via apps, credit cards, and so on) that are seriously out of sync with pre-negotiated procurement contracts. Since many procurement organizations still run legacy infrastructure and hope to get by with fragmented data, they have little-to-no visibility of “rogue” spends. Such unmanaged transactions account for up to four-fifths of a business’s total spend! So, before a business even realizes it, these maverick payouts would have taken a big bite out of its bottom lines. Plus, there are various supply-side headwinds that CPOs must be wary of such as geopolitical instability, extreme weather challenges and pandemics. Hence the need to situate risk management at the core of your procurement strategy.

Cost reduction is a step in the right direction

The impact of cost on profitability can never be overstated, so it’s only natural that a procurement strategy in order to be effective should be concerned about any cost that has a direct bearing on margins. To thoughtfully reduce “wasteful” efforts and work through seemingly insoluble difficulties in combating cost, businesses need line of sight to their spend data. Automating the procurement function will ensure CPOs have access to the consistent stream of clear and accurate data (“single version of truth”) they need to make better decisions to reduce cost and improve efficiency. With automated procure-to-pay infrastructure in place, maverick spends that typically fly under the CPO’s radar now start to get noticed, and those dripping taps can be turned off in no time. That’s procurement strategy at work!

Keep an eye on the “high risk/high profitability” matrix

In order to be successful, any long-term plan for cost-effectively acquiring inventory must assign each procurement “event” to one of four quadrants on the risk-profitability matrix as below. From a procurement strategy standpoint, events with a high-risk/high impact on profitability are particularly significant, and these should get the most attention, care, and caution from sourcing teams. Conversely, activities with low risk/low impact on profitability are not of much consequence and shouldn’t be claiming too much of the CPO’s bandwidth.

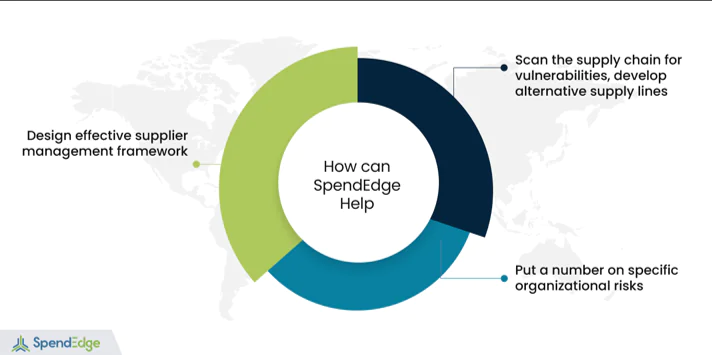

How SpendEdge can help you

Design effective supplier management framework

Risks represent an existential threat for any organization, so recognizing and addressing specific risk factors is of utmost importance. Our experts help businesses build and adopt right-fit templates for sourcing, vendor selection, contract negotiation, and cost management. Our advisors also assist CPOs in uncovering potential risks in the procurement function and generate an impactful procurement strategy to contain or eliminate them.

Scan the supply chain for vulnerabilities, develop alternative supply lines

Any supply chain, as they say, is only as good as its weakest link. So, if any node in the supply chain fails to provide necessary inputs for the next one in line, the disruption could cascade across the supply network. At SpendEdge, our experts in procurement strategy work with client teams to trace disruptions to their root causes and enable businesses to embrace approaches, like diversification, inventory management, and stakeholder communication. This should prevent any recurrence of such unwelcome incidents. Many businesses also work with us to frame cost-friendly yet highly effective contingency plans to deal with unpleasant business interruptions.

Put a number on specific organizational risks

Specifically for quantifying and controlling supplier risks, we have a home-grown tool – D-Risk, which is predicated on more than two decades of our experience in procurement strategy and market intelligence. The D-Risk platform is much favored by businesses across industries for measuring and curbing supply-side risks. The tool scans internal and external risk factors, geopolitical trends, operational stability, costs, and brand reputation to arrive at numbers that precisely reflect risk levels.

Success story: A pharma enterprise builds a procurement strategy that wraps around compliance and risk management

Our client is a global pharmaceutical company with a diverse portfolio of prescription medicines and over-the-counter therapeutics. With a view to pushing the frontiers of therapeutic research, our client runs wide-ranging alliances with public sector and commercial organizations. The client has an impressive track record of successfully applying theoretical knowledge to drive commercial production of new drug formulations at scale and speed. This is bringing much-needed therapeutic relief to patients with high unmet needs. The pharma enterprise boasts end-to-end manufacturing processes capable of seamlessly transforming input materials into finished pills without pauses. The client operates against the backdrop of ever-evolving legislations and a regulatory framework that lays emphasis on product safety, efficacy, and quality. The client’s procurement strategy teams work with an expansive network of suppliers, covering raw materials, active pharmaceutical ingredients (APIs), and packaging materials. For the most part, the client counts on this extended vendor network to ensure the suitability of end products for their intended use as well as promote compliance with tightening regulatory norms. The industry, by its very nature, tends to be affected by potential supply-side risks, and past performance by supply chain participants is no guarantee of future outcomes. Supply chain breakdowns can take pharma businesses unawares in this age of simmering geopolitical tensions. Recalling poor-quality drugs is sure to put pharma companies’ brand image under the regulatory scanner and businesses often have a hard time restoring customer confidence. A lapse on the part of a single supplier is enough to sap the strength of the entire supply line. At the same time, the penalties for compliance-related violations are stinging. For context, fines in this category have crossed $50 billion in the last two decades in the US alone! So, the long and short is that the client started looking out for a more effective supplier risk management strategy. In mid-2022, the pharma business had a kickoff call with our procurement strategy teams.

As they say, one thing led to another, and our procurement strategy specialists framed a rigorous supplier selection process to enable the client to vet potential suppliers more accurately. Fiscal stability, skill sets, as well as compliance and quality management practices were the key parameters in this exercise. Managing customer experience and expectations was the other yardstick. Our experts also organized potential risks clinically into buckets based on severity levels. This apart, our study plumbed the depth of the client’s relationship with tier-1 suppliers and examined the extent of collaboration with the supplier base. Furthermore, our team helped the client deploy a monitoring system to track supplier performance, financial health, and regulatory compliance – all in real-time. To future-proof the supply lines for critical materials, our team recommended diversification of the client’s supplier base and routes. Additionally, our experts in procurement strategy put in place redundancy measures such that the client’s supply lines transition in quick time to alternative sources to abate supply disruptions and associated risks.

Our supply chain management solution is paying off for the client in terms of reduced exposure to risks, compliance improvement, and better supply-side agility. Other benefits like reduced costs and strengthened partnerships have also accrued to the client.

Contact us now to solve your procurement problems!

Author’s Details

Ankur Rishi

Vice President, Sourcing and Procurement Intelligence

With more than 12 years of advisory experience, Ankur manages platform content and services within the sourcing and procurement vertical. Over the years, Ankur has provided consulting services to category leaders from chemicals, energy, and packaging industry, on varied topics, such as category strategy, spend analysis, commodity pricing, and clean-sheet analysis.