By: George Mathew

In the rapidly changing realm of the chemical industry, effective inventory management is essential for sustaining operational efficiency and profitability. One effective approach that chemical companies are increasingly adopting is reducing their inventory levels, a strategy known as de-stocking. It involves a careful review of existing inventory levels, the identification of surplus or outdated items, and the execution of measures to reduce them.

De-stocking inventory stands as a vital strategy for cost reduction and value enhancement within the chemical industry. Chemical inventory management system mitigates problems associated with overstocking, such as obsolescence and wastage, while also liberating working capital, optimizing supply chain operations, enabling agile responses to market demands, and minimizing carrying costs. It helps companies operating in the chemical industry to position themselves for sustained growth in the highly competitive market.

Reducing supply chain vulnerabilities through effective procurement strategies:

Reevaluating lead times to maintain elevated inventory levels

Continuous monitoring and assessment remain crucial throughout the process of inventory management system. Regularly examining critical performance metrics such as expenses associated with carrying inventory, turnover rates, and customer satisfaction levels empowers chemical companies to adapt their strategies as required. Utilizing data-driven approaches ensures their ability to consistently make informed decisions in the realm of inventory management.

Forge strong collaboration with suppliers and customers to close the loop

Fostering a robust and closely integrated collaboration with suppliers and customers, chemical companies can effectively establish a closed-loop system that not only facilitates the efficient management of key raw materials from suppliers but also ensures the smooth flow and management of finished products with the company’s customers, ultimately resulting in the reduction or elimination of obsolescent stock, thereby enhancing overall inventory control and operational efficiency.

Being prepared to tackle the shift within the marketing procurement function

Procurement teams also need to be prepared to tackle the changes in the marketing procurement function. Over the past few years, the marketing procurement function has seen a significant shift. While previously the function was limited to buy-sell transactions or focusing on cost savings or supply continuity, the marketing procurement function of present times has to think more strategically to overcome increased competition, achieve cost reduction, establish mutually beneficial relationships with suppliers, gain a clear understanding of the market or assist the organization in its plans to efficiently review spend analytics and category management.

Implementation of Just-In-Time (JIT) inventory management

To maintain effective inventory management, it is advisable to persist with the just-in-case inventory strategy, particularly for single-sourced and critical materials characterized by extended lead times, a category that includes specialized solvents and chemical products susceptible to shelf life limitations; concurrently, it is crucial to establish well-calibrated safety stock levels and seamlessly integrate business input into the restocking process to optimize stock levels, thereby mitigating the likelihood of stockouts and excess supplies that could impact operational efficiency.

Performing routine audits to enhance inventory management procedures

Conducting periodic inventory audits plays a crucial role in maintaining effective inventory management practices, as these audits provide a comprehensive and accurate assessment of current inventory levels, enabling organizations to identify any discrepancies or discrepancies between recorded and actual inventory, and subsequently allowing them to implement targeted corrective actions and strategic improvements to optimize their inventory control processes, reduce costs associated with overstocking or stockouts, enhance operational efficiency, and ultimately bolster their overall competitiveness within their respective markets.

How SpendEdge can help overcome procurement challenges

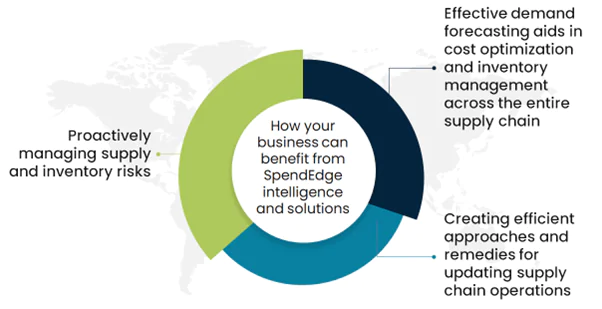

Effective demand forecasting aids in cost optimization and inventory management across the entire supply chain

Procurement advisory, demand forecasting, and inventory management are vital aspects of supply chain optimization. Our advisors assist client in supplier selection and contract negotiations. Our experts utilizing demand forecasting predicts the future customer demand, aiding procurement decisions. Inventory management ensures optimal stock levels, reducing carrying costs and stockouts. Together, these functions create an efficient and cost-effective supply chain, enhancing customer satisfaction and profitability.

Creating efficient approaches and remedies for updating supply chain operations

Our advisors are pivotal in supply chain management, where they adapt strategies in response to supply chain updates and uncertainties. They use data analytics to inform decisions, manage risks tied to inventory levels, and collaborate with inventory managers to prevent inventory overshoots or falling below defined thresholds.

Proactively managing supply and inventory risks

Our experienced advisors to reassess the risks and benefits of stockpiling in the company’s supply chain. Our experts define clear objectives, gather data, conduct a comprehensive risk and cost analysis, and explore optimization strategies. Utilize scenario planning to model various stockpile scenarios and make informed decisions about stockpile levels and policies. Our experts help in implementing chosen strategies, communicate changes to stakeholders, and continuously monitor and adapt to evolving market conditions. This proactive approach will enhance supply chain resilience while optimizing operations.

Success story: How SpendEdge helped our client

Our client is the US-based a mid-sized chemical manufacturer producing a range of specialty chemicals for various industries.

The client has experienced fluctuating demand for its products due to market volatility, seasonal variations, and changing customer preferences. As a result, they have encountered challenges related to excess inventories and quality control.

The solution offered by our experts helped the client to adopt proactive strategies to optimize inventory levels, enhance demand forecasting, and maintain rigorous quality control measures to mitigate financial, operational, and quality risks.

Contact us now to solve your procurement problems!

Author’s Details

George Mathew

Associate Vice President, Sourcing and Procurement Intelligence

George is a procurement specialist at Infiniti Research and provides advisory services to clients across the pharmaceutical, CPG & FMCG, energy, and automotive sectors. He specializes in the procurement areas of industry benchmarking, cost modeling, rate card benchmarking, negotiation advisory, and supplier intelligence.