Author: Christoph Zacharias

E-procurement and the key points some businesses are missing

Electronic procurement (e-procurement), in its essence, is about leveraging the global network of computers and networks to consolidate all of an organization’s purchase activities and, furthermore, simplify the procurement function by eliminating unnecessary steps. The object of this exercise is to move routine procurement functions, such as requisitioning, ordering, and transaction management online. In the process, e-procurement supply chain management replaces manual processes, notorious for killing organizational productivity and wasting money, with instant online applications. The overarching effect is that manual intervention, and along with it the scope for human errors, gets significantly reduced, all the way from requisition to order fulfillment.

Moreover, with centralized tracking and granular reporting of transactions as well as streaming of consolidated metrics on to dashboards, e-procurement supply chain management provides enhanced visibility of procurement processes and tasks with all the precision CPOs typically look for. One thing leads to another, and more accurate views of procurement activities will help teams size up their spend data and devise new ways they had never thought of before to slash costs. Such resource-saving measures might include bringing more suppliers to the negotiating room to bring some extra pressure on the parties across the table and get them to agree to better prices and terms.

A quick view of e-procurement automation

E-procurement tools you must know about

Here’s a run-through of how in actual practice e-procurement supply chain management works to deliver the goods. Bear in mind, there are multiple software tools in the market that cover various steps in the procurement process flow. The more comprehensive solutions address key tasks and activities like requisition and approvals, purchase order, receipt (of goods or services), invoicing, and payment. On the other hand, modular solutions are targeted toward the needs of specific functions such as approvals, contract management, spend management, and RFQ processing. These sit well with incumbent procurement platforms, and, in our experience, businesses should be able to get these technology pieces to “talk to each other” without too much effort.

How e-procurement tools work their magic

E-procurement tools automate critical aspects of procurement like data exchange between parties and assessment of potential suppliers. These e-platforms can easily manage bids for specific goods or solutions from a large number of potential vendors. Based on a convergence of qualifying criteria (e.g., price, quality, delivery time, reliability, skills, experience, ESG certification), the tool picks the most optimal supplier. Besides, e-procurement supply chain management platforms ensure transparency, and, further, make sure all bid participants are treated equally. A catalogue-based ordering system, which is within easy reach of all employees, rubbishes age-old paper-based ordering for good! After this, legacy ordering systems ill-famed for nibbling away at business’s productivity and heightening risk of data errors have no place to go – but into perpetual oblivion!

The results

By reducing manual touchpoints in processes, e-procurement significantly shrinks the duration of various “sourcing events,” thus cranking up the pace of the procurement game, overall. The risk of human errors also recedes, and this has the effect of enriching data quality. This leads to more improved purchase decisions. By centralizing and automating activities, e-procurement supply chain management is able to provide businesses with the real-time insights they need to drive up purchase efficiency.

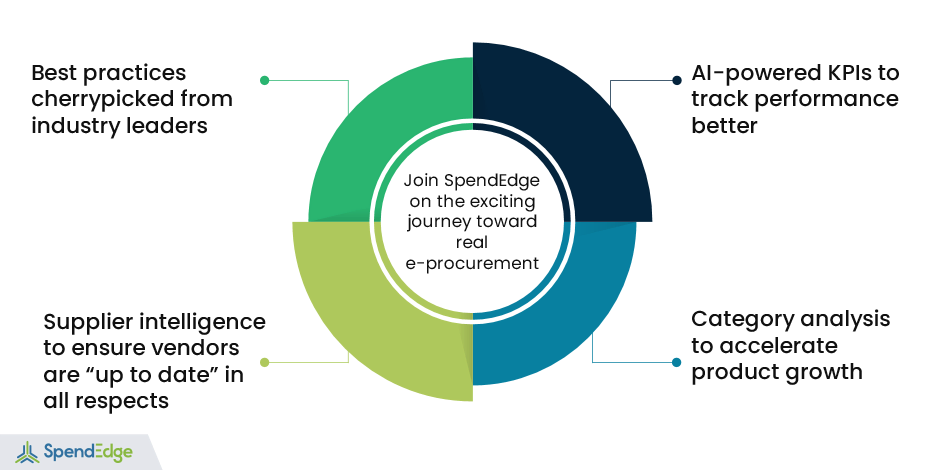

How SpendEdge can help you

At SpendEdge, our experts help businesses across industries size up the market for critical input materials, and this includes in-depth studies of market trends, supply-side metrics, and potential risks to the business springing from multiple unforeseen sources. Our depth and breadth of insights, including on e-procurement supply chain management, enables businesses to make better choices, and this is having a measurable impact on bottom lines and customer perceptions. Our experts will help you identify customer behaviors in large volumes of data and decode them effectively. The best part is you get “all-in-one-place” views of cost drivers and market-shaping trends.

Our clients benefit from an ever deeper understanding of supplier innovations and technological advancements that could potentially impact decisions around e-procurement supply chain management. What’s more, the due diligence we exercise in the vendor onboarding process and frequent validation of supplier data ensure only the best-fit vendors make it to the final shortlists we pass on to clients.

Our experts will handhold you every step of the way when it comes to framing key performance indicators (KPIs). Our expertise extends to the provision of robust service-level agreements (SLAs) for contracts, and the objective is to help clients keep risks down to a bare minimum while ensuring supply chain participants are held accountable for their actions.

Procurement recharge plans for a European business engaged in particulate matter removal

Based in Western Europe, with sales offices in more than 40 countries around the world, our client is focused on technologies aimed at particulate matter removal in industries like manufacturing, automotive, and chemicals. Procurement remains a sore point for many enterprises. It can hardly be otherwise, given the twists and turns in building and maintaining supplier relationships. Balancing the triad of quality, costs, and risks can be a tight rope walk as well. The point is that our client is actively working to remedy the situation instead of sitting back and hoping the matter will simply blow over in due course.

The client has been grappling with the issue for a while now. It all started with the company placing bulk orders for specialty thermal insulation material from a large vendor in East Asia. The client had exercised sufficient due diligence before choosing to go with the particular vendor. Moreover, the supplier is a global provider of insulation materials, including polyurethane, with good credentials and brand identity. But still, our client was facing hassles across multiple stages of the e-procurement supply chain management process. Order placements were getting delayed and so were deliveries. Supplier payments and product inspections were also running behind schedule. In early 2023, the client’s CPO engaged us to generate the metrics and insights needed to improve the performance of the procurement process along parameters like cost, error rate, speed, and visibility of spend dollars.

At the first level, our experts undertook a benchmark study of the client’s procurement processes (versus industry-leading practices). Since raw material quality has been a nagging issue, our team created an alternative supply base for specialty thermal insulation material, the input material in question. The best-fit companies were short-listed based on their expertise, process maturity, capabilities in e-procurement supply chain management, and a host of other criteria. Our insights have already jumpstarted the relationship with the current vendor. The contract with the vendor, in any case, is coming up for renewal in less than a year, so the client has ample options on hand. Fulfillment rates and delivery turnarounds are up several notches. Certain key pieces of the sourcing infrastructure (e.g., procurement performance) are still run in manual mode. As a next step, our experts recommended moving these as well under the e-procurement supply chain management umbrella for improved efficiency.