The primary goal of sustainability in packaging is to minimize resource consumption, reduce waste, and mitigate environmental and social impacts. This involves using renewable and recyclable materials, optimizing packaging design, promoting responsible sourcing and production methods, and ensuring effective recycling or composting.

Sustainability in consumer packaging

The consumer packaging industry is shifting toward sustainability, with the global sustainable packaging market projected to grow at a 7.70% CAGR from 2022 to 2031. Driven by environmental concerns and evolving consumer preferences, the booming green packaging market features innovative materials, smart design, and supportive regulations.

Why go green? – Factors driving sustainability

Consumer preferences

Consumers are demanding greater transparency from brands regarding their environmental practices. They prefer products with minimal environmental impact, are willing to pay a premium for sustainable packaging, and are increasingly concerned with how products are sourced, manufactured, and packaged. According to a survey, consumers in the Asia-Pacific region are more eco-friendly concerned than the global average.

Regulatory pressure

Governments worldwide are enforcing stricter regulations and incentives to promote sustainable packaging and reduce environmental waste. Measures include bans on single-use plastics, mandatory recycling targets, and tax incentives for eco-friendly packaging. Industry standards like the Forest Stewardship Council (FSC) and the Sustainable Packaging Coalition (SPC) guide sustainable practices. Since 2009, the US Environmental Protection Agency (EPA) has promoted recycling and reduced packaging waste through initiatives like the Sustainable Materials Management Program (SMM).

Some of the recent sustainable packaging regulations and initiatives enacted by governments by region:

| Region | Year | Sustainable packaging regulations and initiatives |

| North America | 2016 | In the US, California, Colorado, Delaware, New York, New Jersey, Oregon, and Vermont have enacted bans on single-use plastic bags. |

| 2018 | Additionally, several states in the US have passed legislation to limit the use of Per- and Polyfluorinated Substances (PFAS) in food packaging. | |

| 2019 | The Government of Canada launched the Canada-wide strategy on zero plastic waste goal by 2030. | |

| 2022 | The California State AB 793 Act stipulates plastic beverage container companies must include at least 15% recycled content starting in 2022. The recycled content requirement increases to 25% in 2025 and 50% in 2030. | |

| Europe | 2019 | The Packaging and Packaging Waste Directive set out regulations concerning packaging materials, recycling quotas, eco-design principles, and ban on specific single-use plastic products. |

| 2019 | Germany adopted the Packaging Act, which emphasizes waste prevention, recycling targets, and EPR. | |

| 2020 | The EU’s Circular Economy Action Plan established ambitious goals for recycling and waste reduction. It emphasizes product design and promotes circular economy practices and sustainable consumption. | |

| 2022 | The UK has introduced a Plastic Packaging Tax, which imposes a tax on plastic packaging that contains less than 30% recycled content. There are also bans on certain single-use plastics. | |

| Asia-Pacific | 2018 | The Chinese government established recycling goals, imposed limitations on non-degradable packaging, and rolled out waste sorting programs in major urban centers. |

| 2018 | Australia’s National Packaging Targets set ambitious goals for sustainable packaging, aiming for 100% recyclable, reusable, or compostable packaging by 2025. | |

| 2023 | The government of India adopted the Plastic Waste Management Rules of 2023, which stipulates that all companies comply with EPR. Non-adherence can result in penalties, sanctions, or suspension of business operations imposed by the Central Pollution Control Board. |

Corporate sustainability commitments

Many companies (25%-50%) have committed to sustainability goals, focusing on full recyclability, increased use of recycled materials, reduced plastic usage, and packaging innovation. Growing awareness of climate change and its impacts has led to a demand for more eco-friendly packaging options. Companies are seeking ways to reduce their carbon footprint and mitigate environmental damage. The widespread issue of plastic pollution has prompted calls for alternatives to traditional plastic packaging, with a strong push toward using biodegradable, compostable, or recyclable materials. Corporate sustainability commitments involve initiatives to minimize environmental impact while meeting consumer demands, with several companies adopting innovative strategies and making significant investments to achieve these goals.

Hurdles on the road to green – Challenges for sustainable packaging

High costs

Higher material costs: Sustainable packaging materials often come at a higher cost, typically ranging from 10% to 20% more compared to traditional materials. Transitioning to sustainable packaging often involves using materials like bioplastics, recycled plastics, or compostable materials, which can be more expensive than traditional plastics derived from fossil fuels. For instance, biodegradable plastics or recycled plastics may have higher procurement costs due to limited production scales and higher processing costs.

Investment in equipment and processes: Companies need to invest around 15%-30% more compared to traditional equipment in new equipment and modify existing production processes to accommodate sustainable packaging materials. This investment includes retrofitting production lines, purchasing new machinery for handling biodegradable or compostable materials, and training staff on new processes.

Capacity constraints

Most sustainable packaging companies worldwide are facing a shortage of production capacity as the demand for sustainable alternatives to traditional plastic disposables increases. Sustainable packaging materials often come at a higher cost compared to traditional materials.

Inadequate recycling infrastructure and systems pose significant challenges. Ensuring that sustainable packaging materials are effectively collected, sorted, and recycled requires collaboration across industries and governments. Effective recycling and waste management infrastructure is lacking in many regions, making it difficult for companies to close the loop on their packaging. The lack of robust recycling infrastructure and systems is a major challenge for companies in implementing sustainable packaging solutions.

Technical limitations

Some sustainable materials may not offer the same level of protection or shelf life as traditional plastics. Finding alternatives that maintain product integrity while meeting sustainability criteria can be technically challenging. Sustainable materials, like compostable plastics, may have limitations in terms of functionality and shelf life.

Tech to the rescue – New solutions for sustainable packaging

Biodegradable and compostable materials

Companies are developing plant-based packaging made from materials like corn starch, sugarcane, and cassava. Bio-based packaging materials are revolutionizing the packaging industry by offering eco-friendly alternatives to conventional petroleum-based plastics.

Refillable and reusable packaging

Brands are increasingly exploring refillable and reusable packaging models as part of their efforts to minimize waste and enhance sustainability. These innovative approaches involve designing packaging that can be refilled multiple times or reused for different purposes, aiming to significantly reduce the consumption of single-use packaging materials and promote a more circular economy.

Advanced recycling

Advanced recycling, or chemical recycling, breaks down plastic waste into its basic chemical components, allowing for the creation of new, virgin-quality plastic from recycled materials. This overcomes the limitations of traditional mechanical recycling. Emerging as a crucial complement to mechanical recycling, advanced recycling can process a wider range of plastic waste, including complex multi-layer packaging that is difficult to recycle mechanically. This helps divert more plastic from landfills and supports the transition to a circular economy for plastics.

Success stories – Reaching sustainability goals

Increased use of recycled content

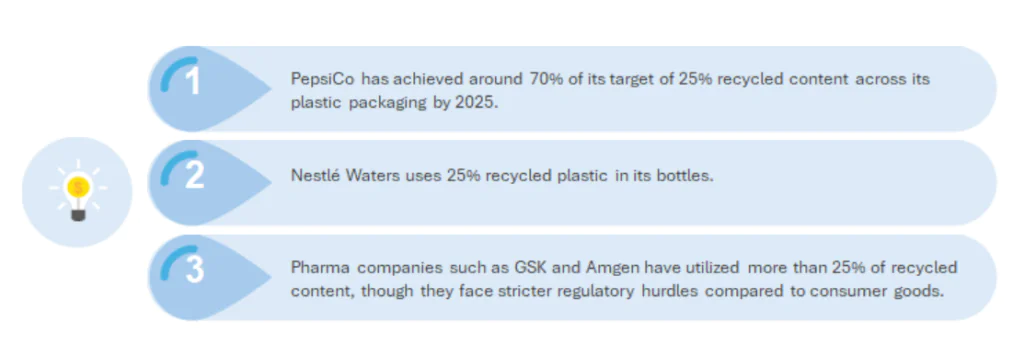

As of last year, several companies have demonstrated their progress toward sustainability targets by incorporating more recycled content into their packaging. Major consumer goods and pharmaceutical companies are making tangible progress in increasing recycled content in their packaging, driven by sustainability commitments, technological advancements, and evolving regulatory frameworks. Collaboration across the value chain will be key to overcoming remaining challenges.

Packaging redesign

Companies are optimizing packaging designs to reduce material usage and improve recyclability. Companies are focusing on “right-sizing” their packaging to minimize excess material and space, while still providing adequate protection for the product. This involves using packaging design tools and software to analyze shipping data and dynamically adjust package dimensions to the optimal size. Adopting lighter-weight materials like paper, cardboard, and bioplastics can also help reduce the overall material usage in packaging.

Partnerships and collaborations

Brands are collaborating with suppliers, recyclers, and NGOs to drive systemic change. By working together, brands, suppliers, recyclers, and NGOs can overcome challenges, share best practices, and scale up solutions to create a circular economy for plastics.

A notable example is the Ellen MacArthur Foundation’s New Plastics Economy Global Commitment, which has garnered over 500 signatories committed to eliminating plastic waste. Signatories commit to ambitious 2025 targets to eliminate plastic waste and pollution, such as 100% of plastic packaging being reusable, recyclable, or compostable and 25% average recycled content across all plastic packaging.

These partnerships and collaborations are crucial for advancing sustainable packaging solutions and fostering a circular economy.

Outlook

Despite ongoing challenges, the industry is progressing through innovation, collaboration, and a strong commitment to reducing environmental impact. The trend toward sustainability in the consumer packaging industry is set to continue, driven by both regulatory pressures and consumer demand. Significant strides are being made toward achieving a circular economy, where packaging materials are reused, recycled, or composted, thereby minimizing environmental impact. By embracing these changes, the consumer packaging industry can contribute significantly to environmental sustainability while meeting the needs of a growing and eco-conscious market.

As the industry evolves, the following trends will continue to shape the future of sustainability in packaging:

- All eyes on circularity: Moving beyond conventional recycling, the industry’s emphasis will be on designing packaging for closed-loop systems where materials are continuously reused and recycled

- Biodegradable/compostable materials: Plant-based and other biodegradable materials will gain traction, minimizing dependence on fossil fuels and promoting waste decomposition

- Minimalist/light weight packaging: Packaging will be designed to use minimal materials while ensuring product protection, reducing environmental impact throughout the lifecycle

- Innovative technologies: Technologies such as nanotechnology and additive manufacturing techniques (3D printing) are being applied to packaging design, allowing for customization, lightweight, and the creation of complex geometries that optimize material usage

- Transparency/consumer education: Clear labeling and consumer awareness campaigns will be crucial for promoting responsible packaging choices and waste management practices.